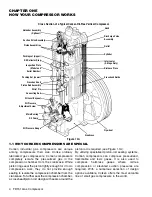

6 FD151 Gas Compressor

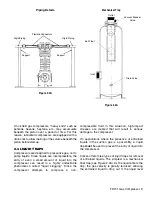

Corken manufactures compressors with one, two,

or three packing sets. Standard-style units contain

one packing set. For completely oil-free

compression, two packing sets are used (see

Figure 1.3A). Oil-free compressors are designated

by the prefix “D". Oil that seeps past the first

packing set is prevented from reaching the second

by an oil deflector ring. Three packing sets and two

distance pieces are available on special machines

for compressing highly corrosive gases. Units with

three packing sets are designated by the prefix "T".

The construction of the "D"- and "T"-style units

ensures that no part of the rod which travels into

the crankcase enters the cylinder.

The distance pieces may be vented or purged with

an inert gas. The orientation of the packing varies

with the application. See Sec. 2.10 and Appendix F

for more details.

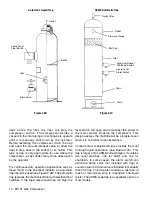

1.4 PISTON/PISTON RINGS

Corken compressors use iron pistons that are

locked to the piston rod. The standard piston ring

material is a glass-filled PTFE polymer specially

formulated for non-lubricated service. Piston ring

expanders are placed behind the rings to insure that

the piston rings seal against the cylinder wall (see

Figure 1.4A).

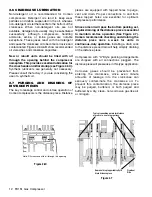

1.5 VALVES

The typical Corken compressor valve consists of a

seat, bumper, spring and valve disk, as shown in

Figure 1.5A. Special heat-treated alloys are utilized

to prolong the life of the valve in punishing non-

lubricated services. The valve opens whenever the

pressure on the seat side exceeds the pressure on

the spring side. The discharge valve is an inverted

version of the suction valve.

1.6 COOLING

Your Corken compressor model FD151 is air-cooled.

It is important to maintain good air flow around your

compressor. Keep this in mind as you select the

location where the compressor will operate.

1.7 SUCTION VALVE UNLOADERS

(OPTIONAL)

Some Corken compressors are equipped with

suction valve Unloaders. Check your model number

against Appendix A to determine the valve/unloader

Gas Pressure Forces

Ring Against Wall

Piston Ring

Groove

Piston Ring

Expander

Piston Ring

Cylinder Wall

Figure 1.4A

Gas flows down from cylinder

Figure 1.5A

Figure 1.3A

Suction Valve

Spec 4, 7, 78, 8, 9

Discharge

Valve

Suction

Valve Seat

Suction

Valve Plate

Suction

Spring

Suction Valve

Bumper

Discharge

Valve Bumper

Discharge

Valve Spring

Discharge

Valve Plate

Discharge

Valve Seat

Distance Piece (‘D’ Style)

V-Ring

Packing

Deflector

Ring

Packing

Spring

Packing

Adjustment

Nut