FD151 Gas Compressor 7

arrangement for your machine. If the valve/unloader

number for your machine is 3 or 4, proceed to

chapter 2 (your machine has no unloaders).

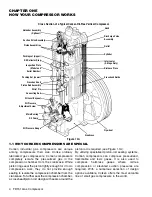

The suction valve unloader is a small piston and

cylinder assembly that is installed over the suction

valve (see Figure 1.1A). The small piston is connected

to a rod that extends into the suction valve assembly.

The unloader piston is depressed when gas

pressurized to 40 psi or more above suction pressure

is injected into the unloader cylinder.

In the depressed position, the piston pushes the rod

against the suction valve disk to hold the suction

valve in an open position. In this position, no

compression will occur, even though the pistons are

still moving up and down.

The unloaders are controlled by devices which

control the flow of gas into and out of the unloader

cylinder. The different types of unloader controls may

be summarized as follows:

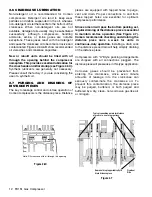

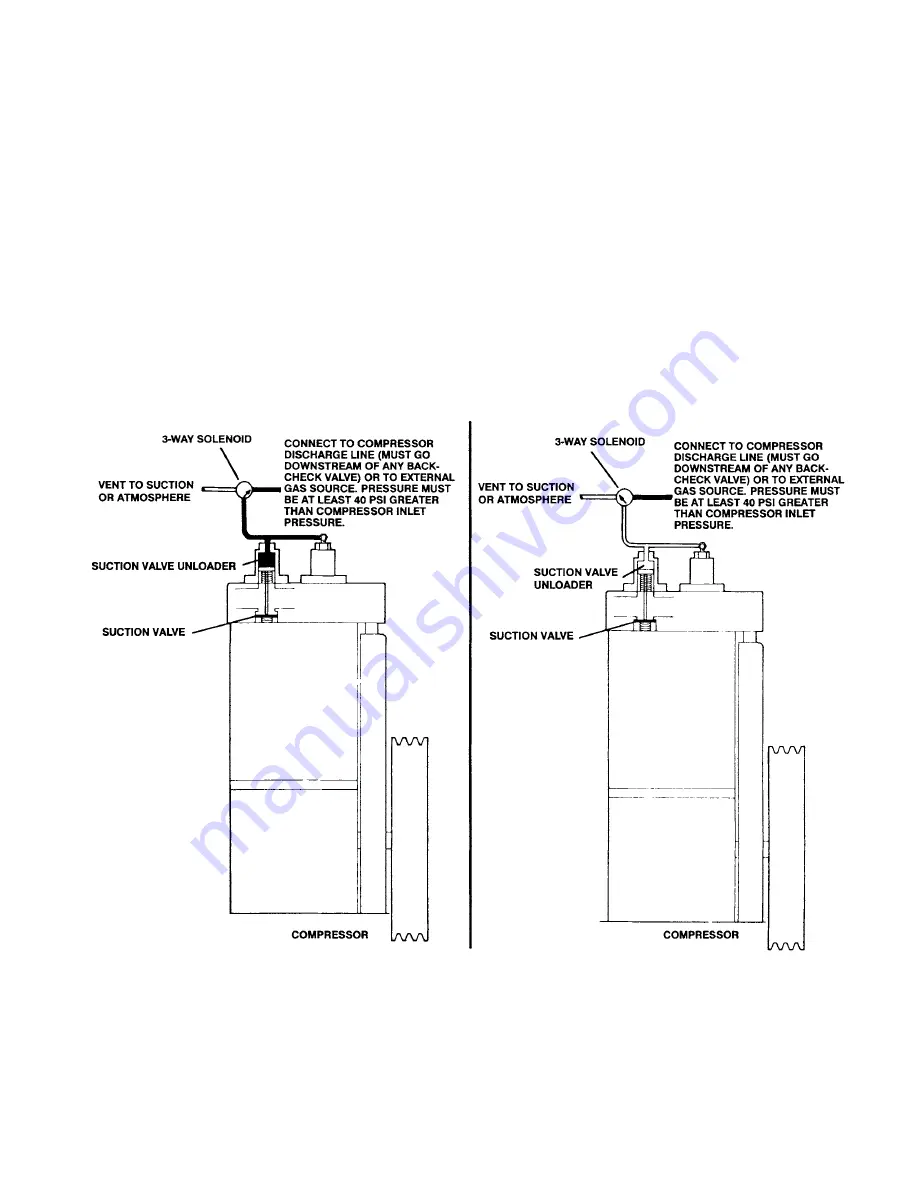

SPECIFICATION 9 - When the gas being

compressed cannot be vented to the atmosphere,

electronic controls should be used as shown in

Figure 1.7D. The use of an optional three-way

solenoid valve allows gas from the unloader to be

vented back to the compressor suction instead of to

atmosphere. A time delay may be used to achieve

loadless start and a pressure switch may be used

to achieve constant-speed unloading.

Specification 9

Figure 1.7D

Unloaded

Loaded