FD151 Gas Compressor 9

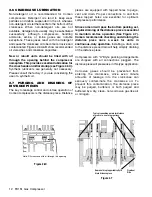

On oil-field gas compressors, "heavy ends" such as

pentane, hexane, heptane, etc., may accumulate

beneath the piston over a period of time. For this

reason, lubricated compressors are equipped with a

drain cock to allow draining of the volume beneath the

piston before start-up.

2.4 LIQUID TRAPS

Compressors are designed to pressurize gas, not to

pump liquids. Since liquids are incompressible, the

entry of even a small amount of liquid into the

compressor can result in a highly undesirable

phenomenon called "liquid slugging”. Since the

compressor attempts to compress a non-

compressible fluid in this situation, high-impact

stresses are created that will result in serious

damage to the compressor.

On applications where the presence of entrained

liquids in the suction gas is a possibility, a liquid

trap

must

be used to prevent the entry of liquid into

the compressor.

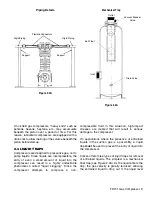

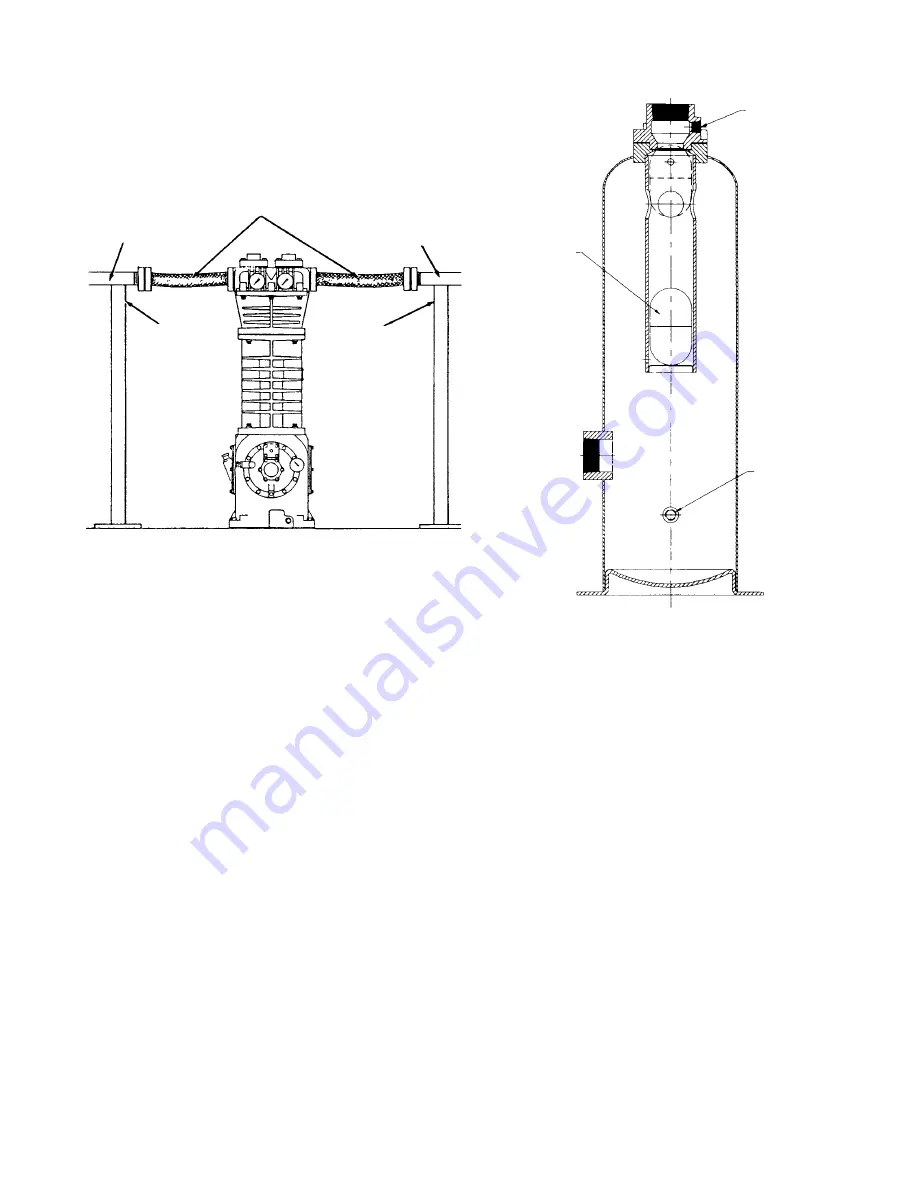

Corken offers three types of liquid traps for removal

of entrained liquids. The simplest is a mechanical

float trap (see Figure 2.4A). As the liquid enters the

trap, the gas velocity is greatly reduced, allowing

the entrained liquid to drop out. If the liquid level

Figure 2.3A

Figure 2.4A

Mechanical Trap

Rigid Piping

Flexible Connectors

Rigid Piping

Support

Support

Outlet

Vacuum Breaker

Valve

Ball Float

Drain Valve

Inlet

Piping Details