30

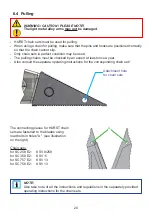

2. Remove the two fixing screws "A" and

remove the protective cover "B". To do

this, first pull the rounded rear edge

outwards and then backwards through

the hand grip, as the edges of the

protective cover adjoining the cylinder

body are kept in place by guide grooves.

If necessary, loosen the hand grip and

move it backwards to obtain sufficient

space to pull it out.

3. Move the blade arms on the until bolt

“E” is easily accessible.

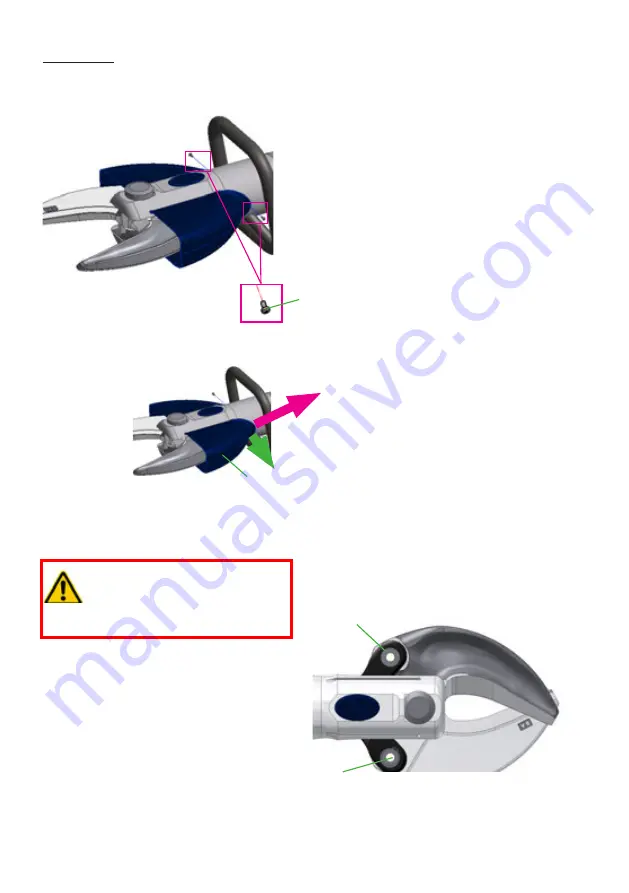

Now switch off the device and

remove the battery or unplug the

power supply from the device.

Work steps:

1. First of all, carefully clean the rescue equipment.

CAUTION / PLEASE NOTE!

When operating the device with

the hand guard removed, there is

an increased risk of injury caused

by the exposed, moving elements.

E

E

B

A

Summary of Contents for HURST eDRAULIC SC 258 E2

Page 43: ...43 14 Notes...