Summary of Contents for Knight On-Premise Pro

Page 1: ...0901133 Rev A 11 13 Page 1 of 20 On Premise Pro Instruction Manual...

Page 16: ...Page 16 of 20 0901133 Rev A 11 13 SYSTEM WIRING DIAGRAM...

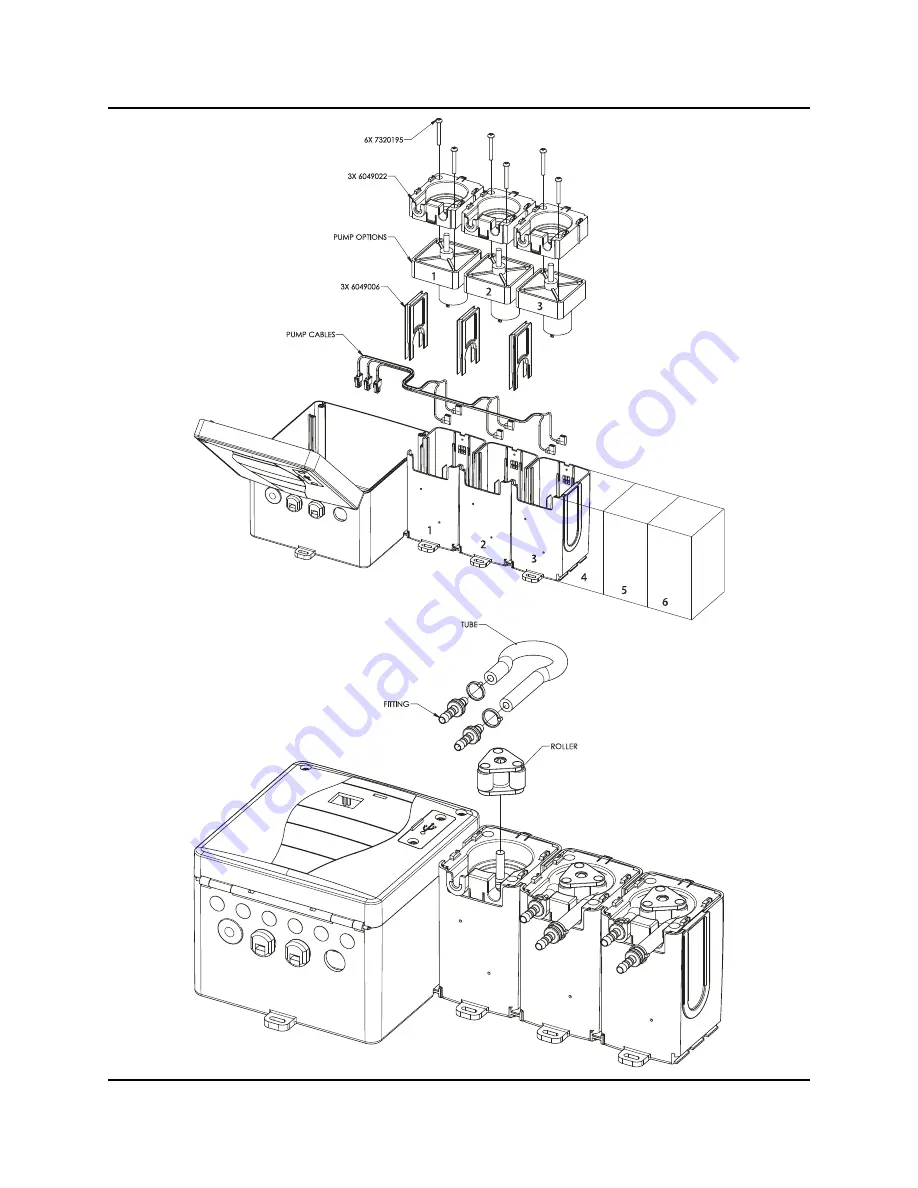

Page 17: ...0901133 Rev A 11 13 Page 17 of 20 SYSTEM PARTS DIAGRAM...

Page 18: ...Page 18 of 20 0901133 Rev A 11 13 SYSTEM PARTS DIAGRAM...