0901082 Rev: D (08/08)

Page 8 of 12

PROBE OPERATION

•

With the detergent power “on”, the conductivity probe

senses detergent concentration. When concentration

drops below the setpoint, the control automatically

turns on detergent feed.

•

Low and high concentration ranges allow easy setting

on all types of water conditions.

•

When the detergent concentration is within 15% of the

setpoint, the control automatically pulse feeds (3

seconds on / 2 seconds off) to prevent over-use of

chemical.

•

An “out of product” alarm will automatically sound if

the detergent setpoint is not reached in a specific time

period.

CONCENTRATION SETPOINT ADJUSTMENT

(1) With low range selected, slowly adjust the

detergent concentration pot clockwise a few

degrees. Detergent will pulse feed, then stop.

(2) Using a chemical titration kit, test detergent

concentration of the wash water. Continue to

increase the pot until the desired setpoint.

(3) If at full clockwise position of concentration pot and

wash water concentration is not strong enough, turn

pot back full counter-clockwise. Switch to high

range.

(4) Slowly adjust pot clockwise until detergent feed

begins, then stops. Using chemical titration kit,

continue adjusting pot until desired concentration

setpoint is reached.

ALARM DELAY SETTING

If the detergent setpoint is not achieved within the time

set on the alarm delay pot, the alarm will sound and the

unit will continue to feed. If the detergent setpoint is still

not reached within a second time frame (double the first)

the alarm will stay on, and detergent feed will stop.

(1) Delay time settings are:

Door

1 to 64 seconds

Conveyor

1 to 128 seconds

(2) For conveyor type dishwashers, adjust the alarm

delay to be slightly longer than the time it takes for

the unit to achieve the setpoint with a fresh tank of

water. For door type dishwashers, the alarm setting

should be calibrated to 5 - 10 seconds less than the

washcycle timing.

(3) Select low or high volume for the alarm.

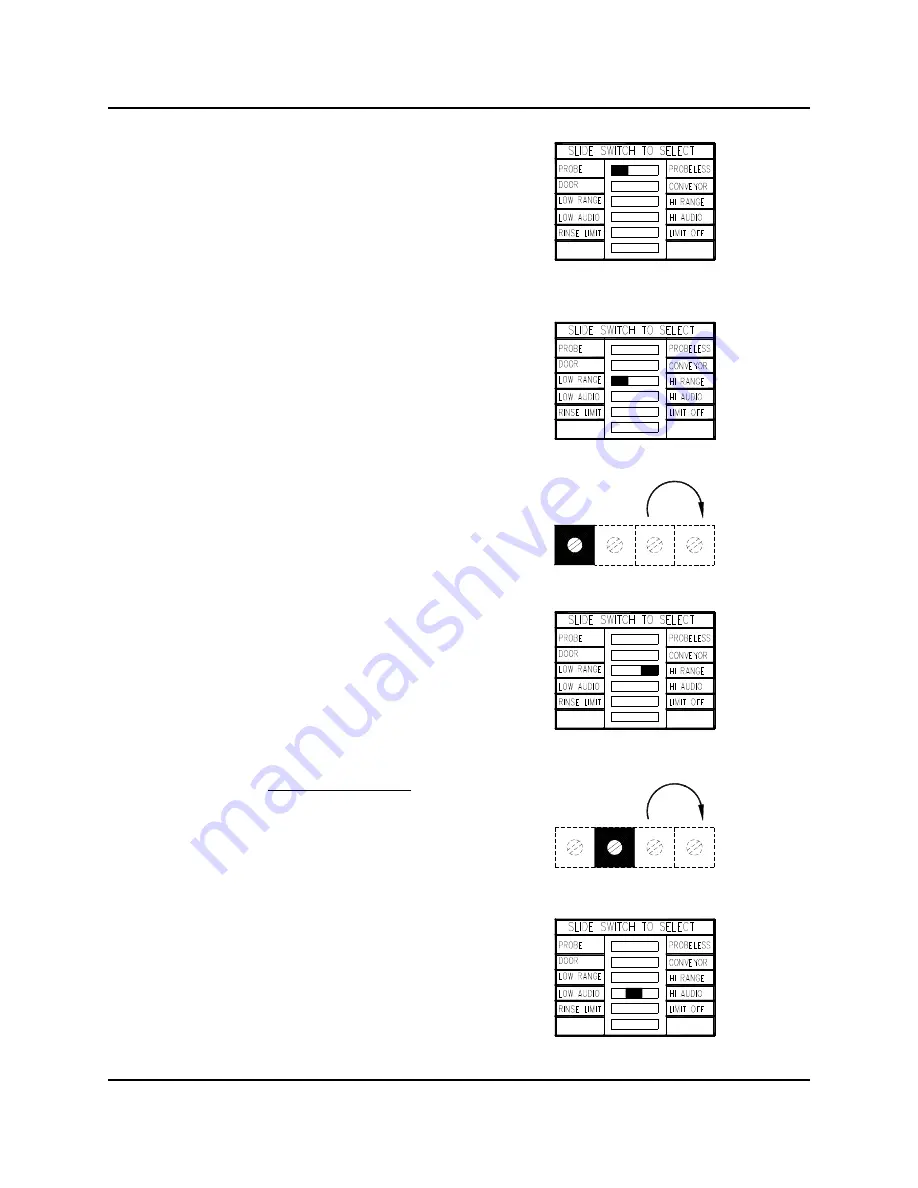

SLIDE LEFT TO ACTIVATE

SLIDE RIGHT TO ACTIVATE

SLIDE LEFT OR

RIGHT TO ACTIVATE

SLIDE LEFT TO ACTIVATE

CLOCKWISE

TO INCREASE

DETERGENT

CONCENTRATION

CLOCKWISE

TO INCREASE

ALARM