P

P

a

a

g

g

e

e

9

9

Page 9

2.5.1 ATEX Information

ATEX Pump Requirements

Mechanical seals are a source of heat and must never be allowed to run dry.

We would recommend provision be made to ensure that there is always flow

or fluid around the pump seals. If there is a risk of the supply being

interrupted, then a temperature monitoring system must be applied to ensure

the pump does not exceed the Atex rating. The surface temperature of the

pump is dependent on the temperature of the pumped fluid and a due account

of this should be taken whilst undertaking your risk assessment of the

installation. These pumps are Atex rated T3.

Only use genuine spare parts that have been designed and verified Atex

compliant by Wright Flow Technologies, failure to use genuine spare parts will

invalidate the Atex certification.

Pumps that have the Atex certification will have an earthing point on the front

cover, this needs to be electrically earthed before use.

The service and maintenance intervals are increased on certified Atex units,

refer to section 3.6.1 for the required routine maintenance. Failure to maintain

the pumps to these intervals will result in the Atex certification being

invalidated.

When installing the unit make sure so far as reasonably practicable that the

pump is aligned within 5 degrees to the horizontal – failure to align the unit

could adversely affect the gearbox lubrication and could cause heat to build

up.

It is the end user’s responsibility to ensure that the Atex rating of the

equipment supplied meets the requirements of the installation.

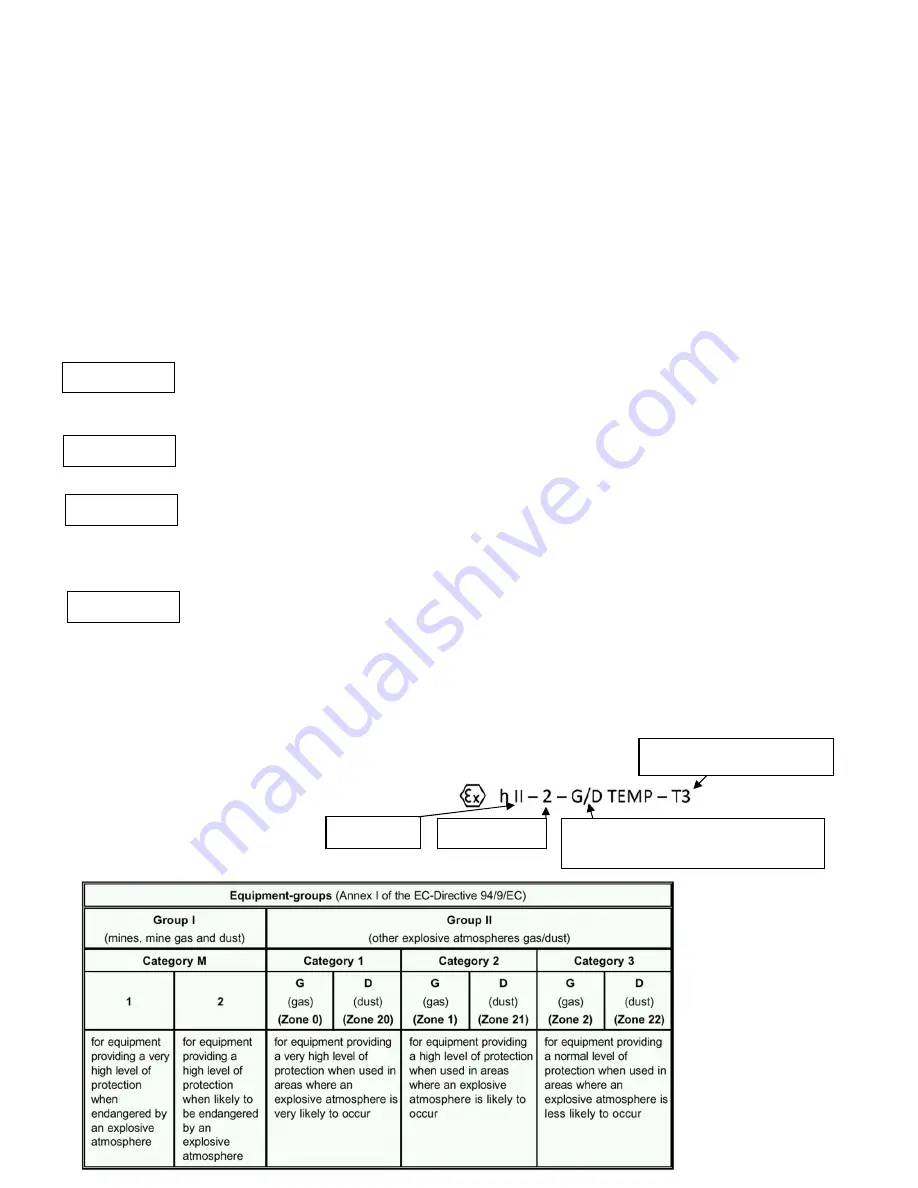

2.5.2 Equipment Groups & Categories

The pump range has been rated as

WARNING

WARNING

WARNING

Category 2

Temperature Class T3

Unit is suitable for environments

containing dust or gas G/D

Group II.

WARNING

Summary of Contents for Wright Flow Technologies RTP Series

Page 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Page 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Page 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Page 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...