P

P

a

a

g

g

e

e

3

3

0

0

They should also not be tightened to the correct torque at this

point, as an adjustment to the timing may still be required.

-

place a nominal amount (0.05 mm) of shim (73) under the rear bearing

cups

-

Install rear bearing (19).

-

Install the shaft assemblies into the gearbox (16) so that the cone and

cup halves of the front bearing (24) are now one unit.

-

Assemble the endplate by installing O-ring (3)

Do not install the rear

lip seal (11) until the bearing pre-load has been set. The lips may

give a false rolling torque reading as well as increasing the risk of

damage during assembly.

-

Install endplate assembly onto the gearbox (16) locating on the dowel

(60).

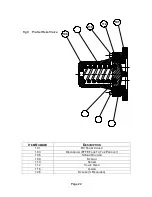

4.2.3 Shaft Assembly – RTP30

-

Install front bearing (24) to the shaft (9 or 10).

-

Install O-rings (26 and 25), to shafts (9 or 10) in the appropriate grooves.

Lightly lubricate all O-rings with a compatible lubricant.

-

Install the gear (14) over the O-rings (26) and secure with retaining bolts

(23). It is recommended that the screws be aligned at the centre of the

slots provided to give an equal amount of adjustment in either direction.

F

F

i

i

g

g

1

1

5

5

S

S

h

h

a

a

f

f

t

t

A

A

s

s

s

s

e

e

m

m

b

b

l

l

y

y

.

.

W

W

A

A

R

R

N

N

I

I

N

N

G

G

Summary of Contents for Wright Flow Technologies RTP Series

Page 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Page 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Page 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Page 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...