P

P

a

a

g

g

e

e

3

3

3

3

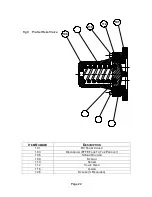

Fig 18 Aligning the mesh point.

-

Remove the shaft assemblies from the gearbox (16).

-

Using the holes provided drill and ream both gear (14) and shaft (9 and

10) to suit Ø6.0 mm dowel (80), as shown in Fig 19. It is important to drill

and ream the hole so that the dowel is positioned equally between the

gears (14) and shafts (9 and 10).

Fig 19 Installing and positioning the timing dowel.

-

Install the Ø6.0 mm dowel into the drilled and reamed hole; applying a

suitable adhesive to ensure that the dowel stays in place.

D

D

r

r

i

i

l

l

l

l

&

&

R

R

e

e

a

a

m

m

t

t

o

o

s

s

u

u

i

i

t

t

Ø

Ø

6

6

.

.

0

0

m

m

m

m

d

d

o

o

w

w

e

e

l

l

.

.

Summary of Contents for Wright Flow Technologies RTP Series

Page 1: ...P Pa ag ge e 0 0 INSTALLATION OPERATION AND MAINTENANCE MANUAL FOR THE RANGE OF PUMPS...

Page 47: ...P Pa ag ge e 4 46 6 5 0 Specifications 5 1 Clearance Chart B A C Radial D C Radial...

Page 54: ...P Pa ag ge e 5 53 3 5 6 Typical Basic Pump Build RTP20 Shown...

Page 56: ...P Pa ag ge e 5 55 5 5 8 RTPTM Service History Pump Serial No Date Comments...