ID GATE 6000 Electromechanical Tripod Turnstile

17

8 INSTALLATION INSTRUCTIONS

Follow the safety requirements during the installation (see Clause 7.1)

8.1 Installation details

Correct turnstile installation provides its functionality and lifetime. Please carefully study

and follow the installation instructions.

It is recommended:

•

to mount the turnstile on steady and level concrete (grade 400 or higher), stone or

similar foundations at least 150mm thick;

•

to level the foundation so that the anchoring points of the turnstile lie in the same

plane;

•

to apply reinforcing elements (400×400×300mm) for installation on less steady

foundation (frame foundation, for example).

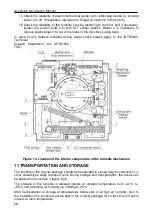

To ensure accurate passage tracking, when the turnstile is operated from an ACS, it is

recommended to create the passage area in such a way that the barrier arms should turn

in the direction of movement at the angle no less than 70° (Fig. 9).

Figure 9. Site preparation. Recommendations

The turnstile is equipped with the resetting device that operates as follows:

o

at the barrier arm turning at the angle of more than 60°±5° the reset is effected in

the direction of movement and the turn of barrier arm to counter direction is not

possible (blocking of return passage) ;

o

at the barrier arm turning at the angle less than 60°±5° the reset is effected

in the counter to the movement direction (reset to home position).

When planning the passage area, it is necessary to arrange additional emergency exit. For

example, it can be the automatic rotary section BH-02 (Clause 9.4).

8.2 Installation tools

•

1.2÷1.5 kW hammer drill;

•

Ø16 mm hard-alloyed drill bits;

•

Floor chaser for electric raceway;

•

Flat slot screwdriver No.2;

•

Cross-head screwdriver;