Innovative DisplayWorks

G-77

9

TROUBLESHOOTING

If your cooler is not working properly:

• Check the electrical outlet for power, and that the plug is properly inserted.

• Check to see if the circuit breaker is tripped or the fuse is blown.

• Check the condenser for proper cleaning.

If your cooler is making noise:

• Check that the cooler is level and on a fl at surface.

If the compressor turns on and off frequently:

• The room temperature is higher than normal.

• The door is not closed completely.

• The door gasket is not sealed well.

• There is insuffi cient clearance around the cooler.

• The temperature is not set properly.

• The cycling frequency will reduce when all of the cans reach the set temperature.

The following is not a malfunction:

• It is normal to hear gurgling sounds caused by the fl ow of refrigerant when each cooling cycle ends.

REFRIGERANT

• The cooler utilizes R600a refrigerant.

SPECIFICATIONS

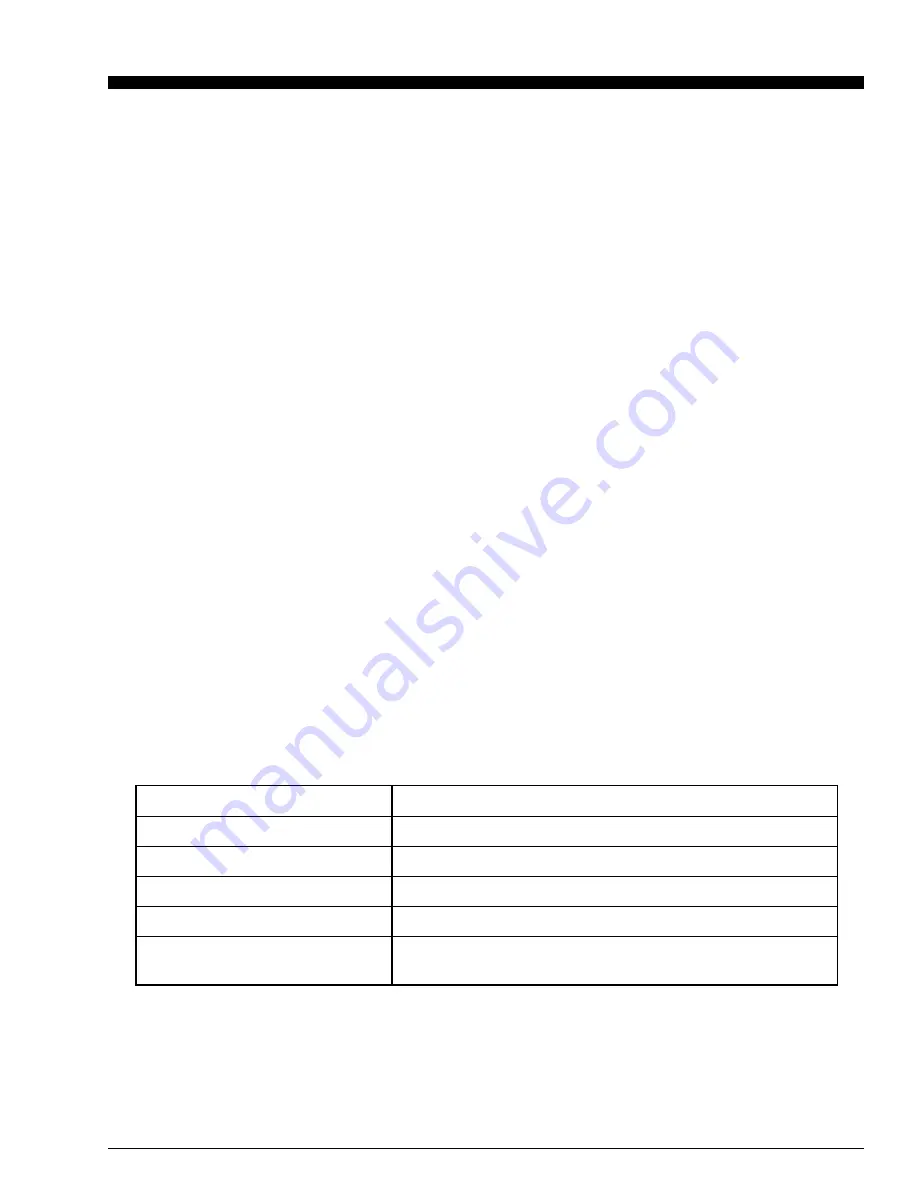

Model:

Power Supply (V/Hz):

Dimension (W x D x H):

Box Dimension (W x D x H):

Maximum Load Per Shelf:

NSF-7 Standard:

This equipment is intended for the storage and display of non-potentially

hazardous bottled or canned products only.

G-77 Electric

G-77 Electrical Impulse Cooler

110V/60Hz or 220V/50Hz

22.25” x 22.25” x 33.25”

23” x 23” x 34”

N/A