Print More Materials, All For Application

20

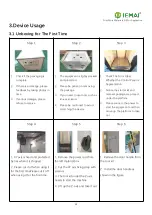

5.3 Temperature Setting of The Constant Temperature Chamber

Step 1

1.

Schematic

diagram

of

the

chamber temperature controller

Step 2

1.

Long press the temperature

setting key to enter the setting

interface

Step 3

1.

Press and hold the set button

unit this position number begins

to jump

Step 4

1.

Set the target temperature with

the transposition key,

increase/decrease key

Step 5

1.

Press Set button to return

Step 6

1.

As shown in the figure output

control indicator 1 lights up and

the temperature rises