EN

4 - HANDLING AND INSTALLATION

SIR 52 MS52 P/F

4 - Pag. 12 / 22

4.4.4 Alignment

INFORMATIONS

Operation to be carried out by IEMCA skilled personnel only.

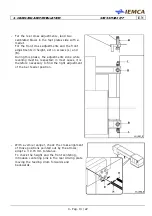

- Stretch a nylon yarn (ø 1 mm) between the bar feeder and the lathe collet as mentioned

below:

• assemble yarn-holder block (E) instead of the last pair of reels;

• position a cap (F) with hole ø 1,5 mm.( to be manufacted by the client ) in the lathe

collet;

• ove the feeding drum slightly forwards in relation to the back limit stop and stretch yarn

(G); move the drum backwards and lock sliding to keep the yarn stretched.

INFORMATION:

The alignment of at least two guide channels must be performed.

Summary of Contents for SIR52 MS52 P

Page 2: ......

Page 4: ......

Page 6: ......

Page 20: ...EN 2 TECHNICAL INFORMATION SIR 52 MS52 P F 2 Pag 10 14 2 6 TECHNICAL INFORMATION...

Page 24: ...EN 2 TECHNICAL INFORMATION SIR 52 MS52 P F 2 Pag 14 14...

Page 50: ...EN 4 HANDLING AND INSTALLATION SIR 52 MS52 P F 4 Pag 22 22...

Page 72: ...EN 5 ADJUSTMENTS AND SETTING UP SIR 52 MS52 P F 5 Pag 22 22...

Page 102: ...EN 6 USE AND OPERATION SIR 52 MS52 P F 6 Pag 30 30...

Page 148: ...EN 9 PART REPLACEMENT SIR 52 MS52 P F 9 Pag 16 16...

Page 174: ...EN 11 GUIDE CHANNELS BAR PUSHER REVOLVING TIPS SIR 52 MS52 P F 11 Pag 6 6...

Page 185: ...12 GRIPPERS SIR 52 MS52 P F EN 12 Pag 11 34...

Page 203: ...12 GRIPPERS SIR 52 MS52 P F EN 12 Pag 29 34...

Page 212: ...EN 13 LIST OF AFTER SALES CENTERS SIR 52 MS52 P F 13 Pag 4 4...