41

2

INSTALLATION PROCEDURE

302.061

ERROR

CAUSE

SOLUTION

At the beginning of the first feeding

stroke, the short feed gate is not

closed.

The gate could not close because of

an obstacle.

Check that the area is free from

obstruction (swarf, bar remnants,

chips). Close the gate manually

checking for obstructions.

Gate closed sensor fault.

Check that when the gate moves,

the sensor is triggered.

ERROR

CAUSE

SOLUTION

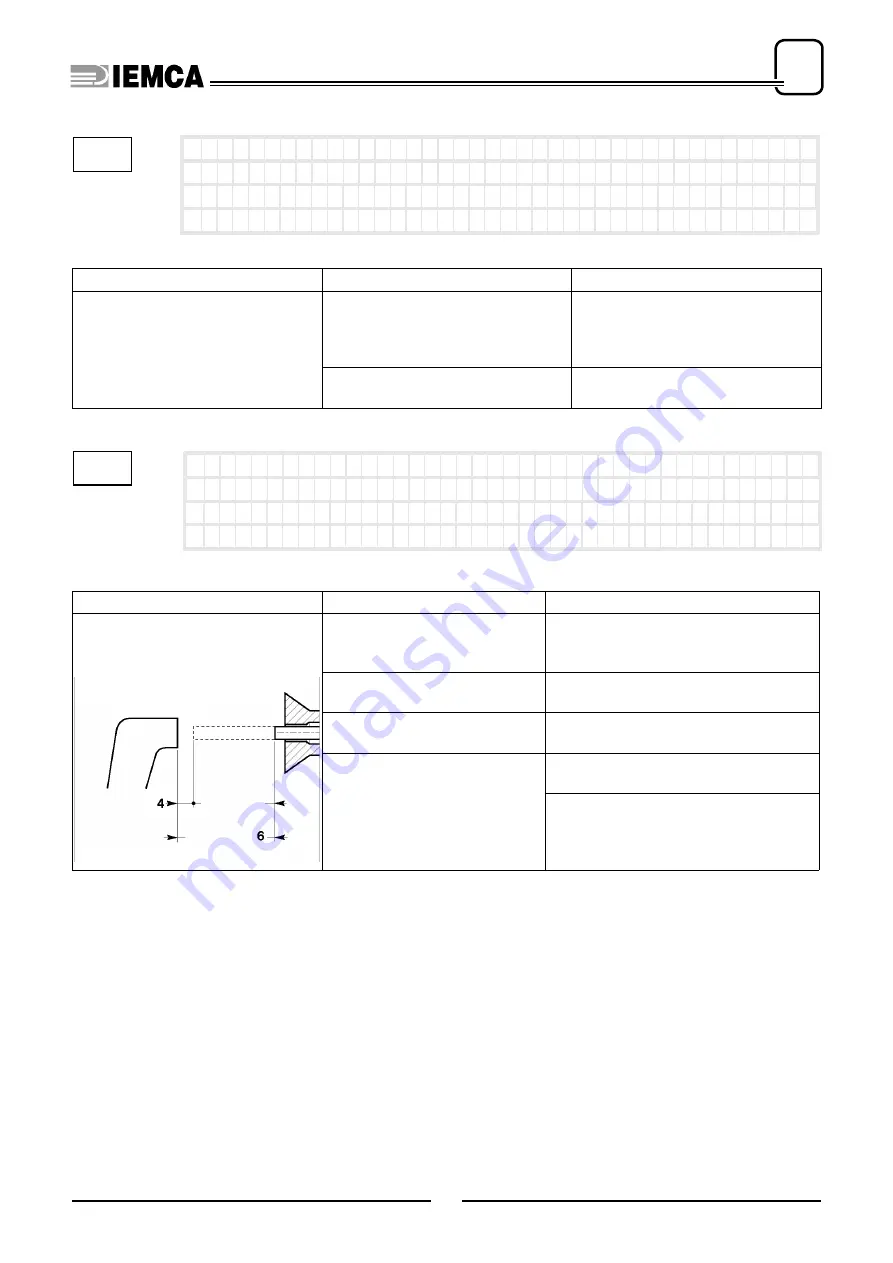

After “collet closed” the bar is at a

position lower than that given by

parameter 6 minus parameter 4

.

The value of

parameter 4

is too

low.

Check the value of

parameter 4

based

on the length of the workpiece to be

machined.

The collet lathe does not open

correctly.

Check the correct opening of the collet

lathe (at least 0.5 mm).

The push on the bar is not suffi-

cient.

Check the values of

parameter 4

, and

parameter 6

.

Encoder fault.

Check that the encoder is driven cor-

rectly in the rotation.

Check on the display the position of the

bar pusher carriage, and verify that the

position change indicated corresponds

to the actual movement.

9

E r r o r : g a t e

o p e n

10

E r r o r : s h o r t

f e e d

parameter

IDM - 61.022 Ec.0

parameter

error 10

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......