43

2

INSTALLATION PROCEDURE

302.061

CAUSE

SOLUTION

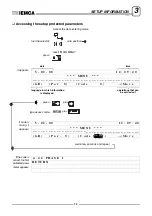

The amount of pieces set has been reached.

Reset the number of workpieces at

parameter 26

, then

restart.

ERROR

CAUSE

SOLUTION

The bar feeder is in AUTOMATIC

MODE and the feed signal is active,

but the bar feeder does not feed the

bar.

One of the lathe door enabling the

signal is open.

Check that the lathe door are clo-

sed.

The “CLOSED DOOR” signal does

not reach the bar feeder card.

Check the lathe output signal input-

ted in the PLC (wire number, port)

The bar pusher stop interface signal

from the lathe is present.

Check the “INTERFACE FROM

LATHE” signal.

ERROR

CAUSE

SOLUTION

The lathe has stopped with the feed

signal ON.

While in AUTOMATIC MODE, the

lathe collet has remained open for a

time longer than the value set in

parameter 22

.

Check the value of

parameter 22

, in

relation to the actual time of “FEE-

DING”.

13

( E r r o r

: . . . )

P r e s e t

q . t y

r e a c h e d , r e s e t ! ! !

14

E r r o r : d o o r

s a f e t y

15

16

E r r o r : o p e n

c o l l e t

t i m e

o u t

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......