69

3

SETUP INFORMATION

302.061

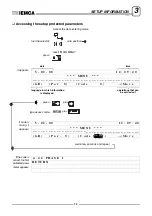

3.1.4 Interface parameters - Description

Subparameters

It defines how to handle the interface signals from lathe to bar feeder.

85

n o . 8 5

I n t e r f a c e

s i g n a l s

B a r

c h a n g e

( 0 = N O / 1 = N C )

0

F e e d

( 0 = N O / 1 = N C )

0

L o a d i n g

c y c l e

( 0 = N O / 1 = N C )

1

M a n u a l / a u t . f r o m

l a t h e

( 0 = N O / 1 = N C )

0

T h r e a d i n g

s a f e t y

( 0 = N O / 1 = N C )

0

F e e d

s t o p

( 0 = N O / 1 = N C )

0

( 0 )

S a f e t y

f r o m

l a t h e

( 0 = N O / 1 = N C )

1

S t a r t

f r o m

l a t h e

( 0 = N O / 1 = N C )

0

S t a r t u p

s a f e t y

( 0 = K 3 7 / 1 = K 1 6 6 ) 1

D o o r

s a f e t y

( 0 = N O / 1 = N C )

0

C h a n g e

mm

< - - >

i n c h e s

( 0 = mm / 1 =i n c h e s ) 0

S t a r t u p

s t a r t

( 0 = N O / 1 = N C )

0

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......