HANDLING AND INSTALLATION

4

30

2.

0

2

8

- 23 -

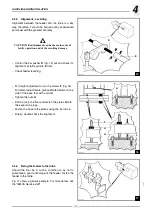

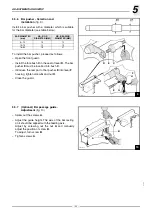

4.5.5

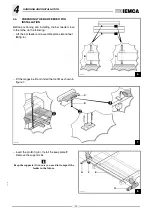

Bar passage guide - Installation

– Saw the guide of the length

L

necessary to cover

the distance between bar feeder and lathe spindle.

– Position it in its seat.

– Adjust the guide height. The bar axis (resting on the

bar) should be aligned with the feeding axis.

– To adjust, turn screw

A

.

– Tighten the nuts

B.

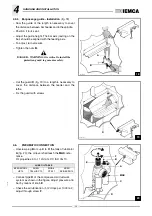

DANGER - WARNING: it is critical to install the

protection guard to guarantee safety.

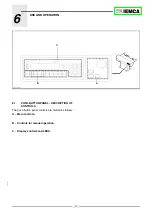

– Cut the guard

D

(fig. 19) to a length

L

necessary to

cover the distance between the feeder and the

lathe.

– Fix the guard with screws.

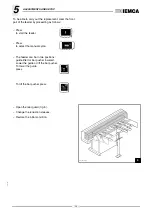

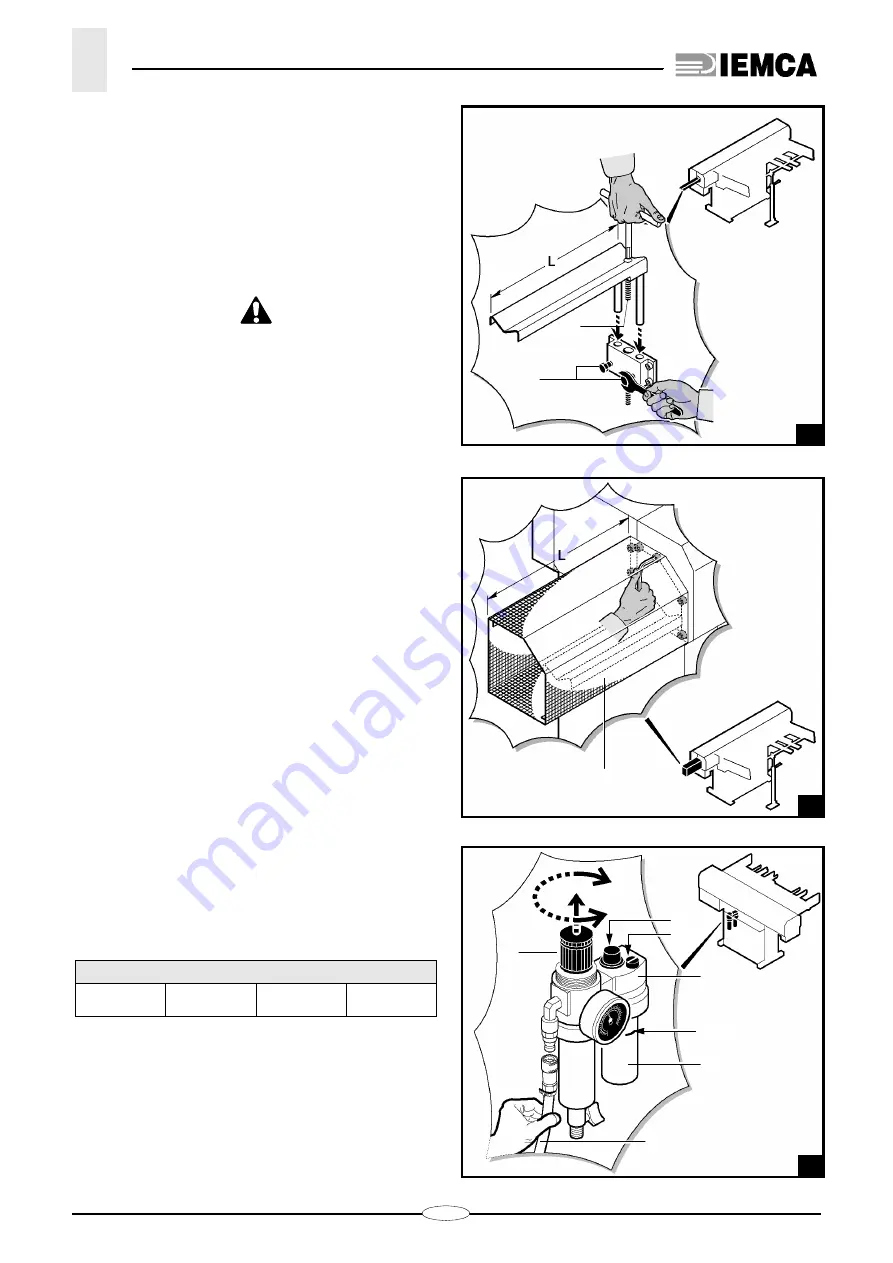

4.6.

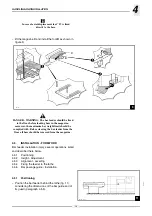

PNEUMATIC CONNECTION

– Unscrew plug

B

or cup

C

to fill the tank of lubricator

A

(fig. 20); the oil level shall reach the

MAX

. refe-

rence.

Oil properties: 9 to 11 cSt at 40°C ISO VG 10.

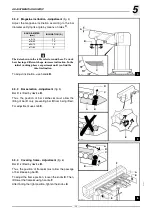

– Connect pipe

D

of the compressed air ductwork

system as shown in the figure. Adjust pressure at 6

bar

by means

of knob

E

.

– Check the air lubrication (1-12 drops per 1000 l air);

adjust through screw

F

.

LUBE OIL TABLE

BP ENERGOL

HP10

SHELL

TELLUS C10

MOBIL

DTE 21

ESSO

SPINESSO 10

28.031 Ec.1

B

A

28.032 Ec.0

D

•

22.080 Ec.0

•

•

•

E

F

B

A

MAX

C

D

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......