USE AND OPERATION

6

30

2.

0

2

8

- 38 -

6.2.

6.3.

BAR STOCK - CHARACTERISTICS AND

PREPARATION

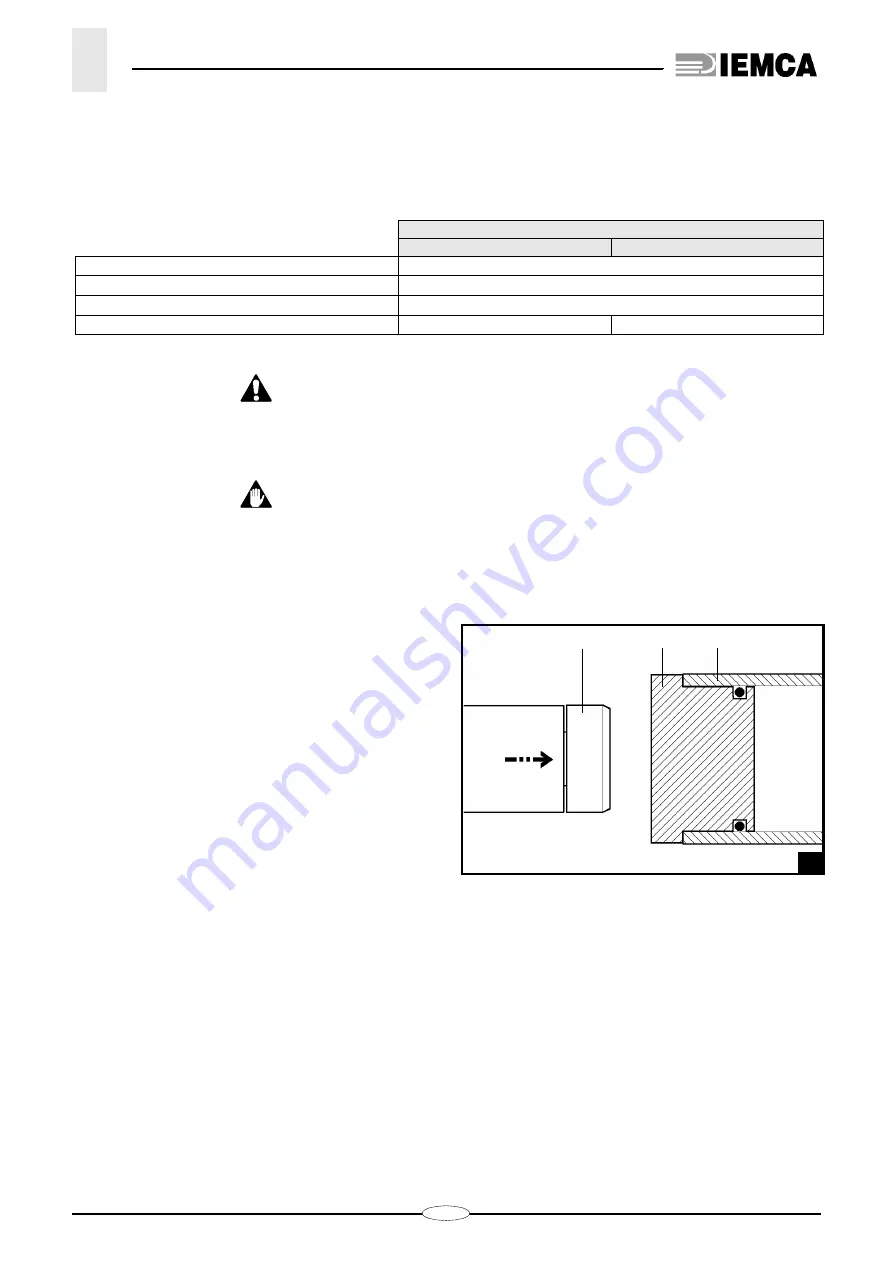

The bar stocks must comply with the features shown in

the table.

DANGER - WARNING: The maximum stock length

must be contained within the lathe spindle length.

CAUTION: Do not feed bars having a different size than

that prescribed by the Manufacturer.

❏

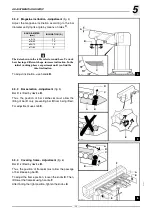

Bars

– Bars should not have too much excess flash at their

fore end. This would affect their feeding into the

lathe collet.

❏

Tubes

– Tubes should not have too much excess flash at

their fore end. This would affect their feeding into

the lathe collet.

– Prepare a cap

to mount into the rear end of

the tube

B

in order to avoid that:

– the thrust of the bar pusher

C

is not transmitted to

the tube

B

.

– the lathe coolant flows out in the feeder.

Model

14

15

Min. bar diameter

ø 5 mm

Max. bar diameter

ø 80 mm

Min. bar length

250 mm

Max. bar length

1400 mm

1560 mm

28.056 Ec.2

B

A

C

•

•

•

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......