32

2

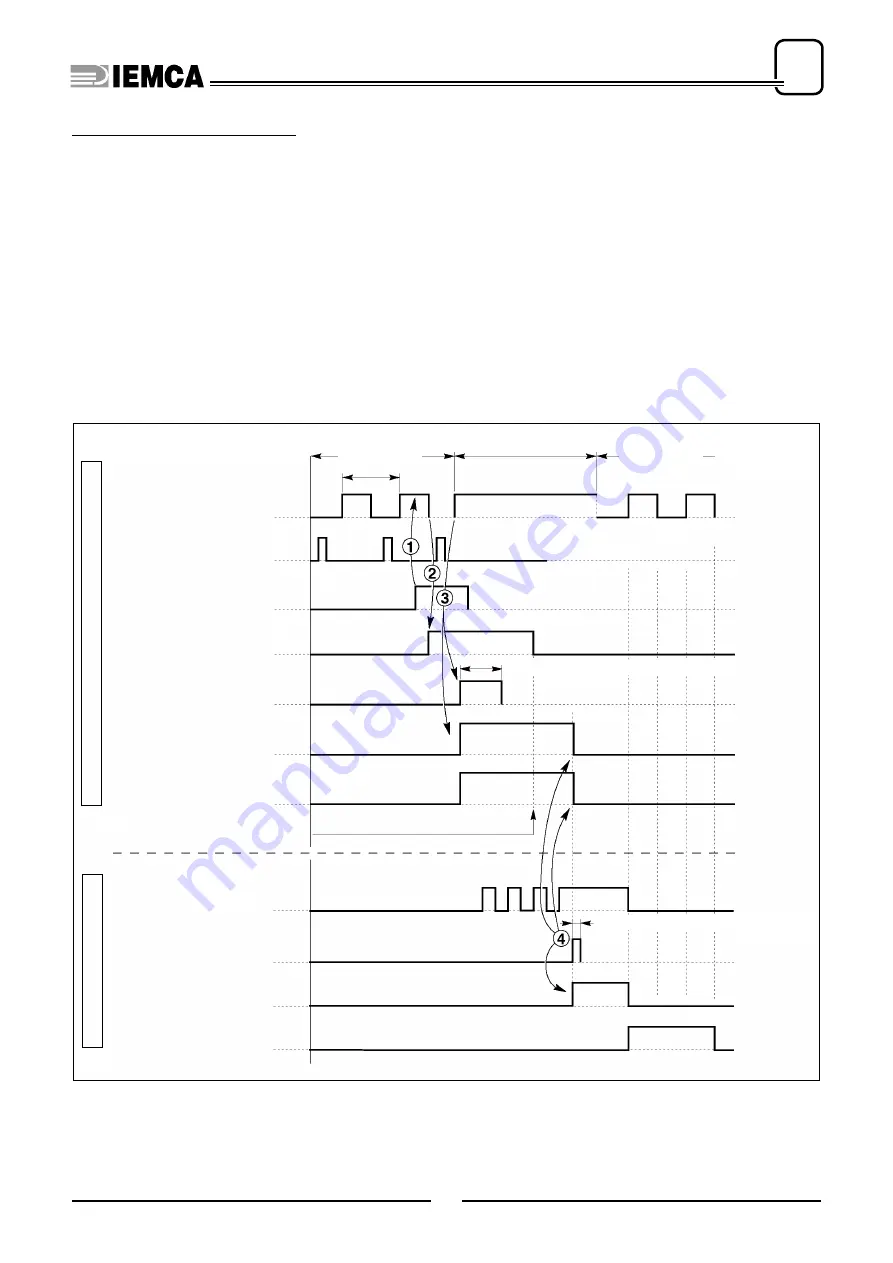

INSTALLATION PROCEDURE

302.061

As far as “BAR CHANGE-OVER” signal control is concerned, this option dif-

fers from option

1 - (RETURN)

.

Said signal controls more bar-pusher feeding movements, whenever they are

required by lathe during workpiece machining.

In this condition, the “BAR CHANGE” controls the feeding of the bar feeder

and disables its return. The bar feeder return depends on the “FEEDING” si-

gnal.

Interface signal cycle diagram

4 - (FEEDING)

61.030 Ec.0

MACHINING

Feed (OPEN COLLET)

parameter

1

End of material detected by the encoder

K1

BAR END

K13

CYCLE STOP

K19B

CONTINUOUS CYCLE STOP

BA

R CHANGE

-OV

E

R

BAR CHANGE-OVER CYCLE

t

(time adjustable through parameter 38)

t (time adjustable through parameter 37)

K15

CYCLE START

K10

1ST CYCLE DESACTIVATION

K10A

2ND CYCLE DESACTIVATION

K29

SPINDLE IMPULSES

C

Y

CLE

S

T

AR

T

MACHINING

2nd feed

WORK-

PIECE

Bar feeder at the rear limit switch

SPINDLE STOP

K30

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......