- 14 -

3

02.

0

2

8

3

SAFETY PROCEDURES - GENERAL INFORMATION

3.1.

SAFETY GENERAL INSTRUCTIONS

It is of the utmost importance to read carefully this

manual before carrying out any installation, use,

maintenance or other servicing on the machine. The

compliance with the instructions contained herein

ensures safety both of man and machine.

❑

Both the operator and skilled engineer in charge

shall keep to their task.

❑

Do not tamper with the safety devices for any rea-

son whatsoever.

❑

Safety labour regulations issued by each country

authority shall be strictly complied with.

❑

IEMCA declines any liability whatsoever for dama-

ges to people or property due to the non-obser-

vance of the above mentioned regulations.

3.2.

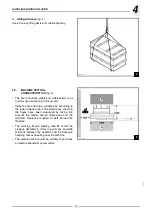

HANDLING AND INSTALLATION - SAFETY

PROCEDURES

❑

Machine shall be handled using suitable means

and methods.

❑

People shall not stand underneath a suspended

load, within the crane, lift truck or other suitable

means of lifting or transportation operating range.

❑

The working and bar feeding area shall be delimi-

ted in order to prevent collisions between the ope-

rator and transportation or handling means, if any,

either of the materials to be machined or other

material.

❑

A proper machine installation, as well as lighting

and cleaning of the area, are of the utmost impor-

tance as far as personal safety is concerned.

❑

The electric system connection shall be carried out

by skilled personnel only.

❑

Make sure the electric system is earth connected

through a suitable cable.

3.3.

ADJUSTMENTS AND SETTING UP -

SAFETY PROCEDURES

❑

Carry out the adjustments according to the use

and maintenance manual.

❑

Do not change the working parameters to obtain

performances different from those designed and

tested.

❑

Do not adjust the machine when it is running

unless otherwise specified in the use and mainte-

nance manual.

❑

Do not feed the machine with barstocks having

dimensions different from those recommended by

the manufacturer.

❑

Do not use hoses as grips.

3.4.

USE AND OPERATION - SAFETY

PROCEDURES

❑

The working area around the machine shall always

be kept clean and empty in order to allow an imme-

diate access to the emergency devices, thus

allowing the bar feeding operations without cau-

sing danger and hindrance.

❑

Carry out the starting cycle sequence as recom-

mended.

❑

Do not introduce hands or other parts near or

inside running parts or energised parts of the

machine.

❑

Take off bracelet, watch, ring and tie.

❑

Whenever necessary, use strong working 5 finger

gloves, which do not reduce sensitivity and grip-

ping.

❑

Use working shoes as well as personal protections

as provided for by the accident prevention regula-

tions in force in every country.

❑

Personnel in charge of maintenance shall be infor-

med should the machine fail to work properly.

❑

Before starting the machine, make sure that there

is no personnel carrying out maintenance or clea-

ning operations.

Summary of Contents for VIP 80

Page 1: ...REL DATA COD S N VIP 80 MANUAL FOR USE AND MAINTENANCE GB 1 03 11 99 805005440 ...

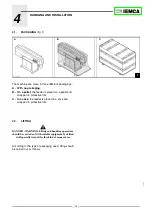

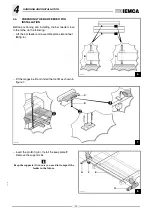

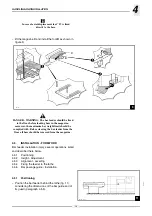

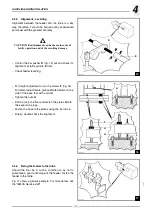

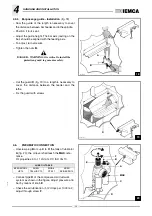

Page 28: ...HANDLING AND INSTALLATION 4 25 302 028 ...

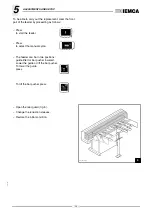

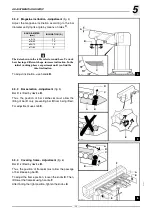

Page 61: ...PUSH BUTTON PANEL OPERATION GUIDE GB 03 11 99 VIP 80 AUTOMATIC BAR FEEDER ...

Page 64: ...2 302 061 ...

Page 74: ...12 1 GENERAL INFORMATION 302 061 ...

Page 136: ......

Page 138: ......

Page 142: ...302 061 B ...

Page 144: ......

Page 148: ......

Page 150: ......

Page 152: ......