Page 92 of 110

Interface

Perform the action requested by the first part of the string and then send CAL MEAS. If the

second part of the prompt is of the form

": Min n.nnn Max m.mmm”

make the requested measurement and enter the value (which will be a voltage measurement); if

the measurement is not in the specified range, something is wrong. The command in this case is

of the form

CAL n.nnn

No units are sent, and the value must be in fixed point format.

If a serious mistake is made when connecting a DUT (such as leaving the fixture OPEN after

being prompted for a SHORT), the calibration MAY fail due to an A/D overload. If the message

“A/D current input ovrrng” is displayed or returned as a prompt, the calibration must be aborted

by sending STOP. There is no way to back up and continue from the last successful part of the

calibration; it must be restarted from the beginning.

NOTE:

The 19xx calibration procedure is designed to allow calibration with a wide range of cables and fixtures. There is no

specification for how big a mistake is required to cause the calibration to fail.

If the FAIL light on the front panel

flashes during calibration, the setup should be rechecked and the calibration repeated.

When a calibration completes normally, the new data are automatically saved to nonvolatile

memory. It is not necessary to send the SAVE:SAVE sequence to cause them to be updated. If

the cal kit data are updated during the calibration, the new values will be saved only after a

successful calibration. If the cal kit data are updated at any other time, it is necessary to send

SAVE:SAVE to cause them to be written to nonvolatile memory.

Unlock the front panel by sending

SYST:

LOCK

OFF

Summary of Contents for 1910

Page 8: ...Page 4 of 110...

Page 10: ...Page 6 of 110...

Page 34: ......

Page 100: ......

Page 107: ...Theory Page 103 of 110 Figure 4 4 Detector Circuits Es IL Ex PL PH Voltage Current...

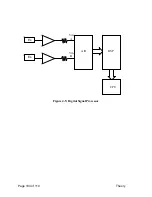

Page 108: ...Page 104 of 110 Theory Figure 4 5 Digital Signal Processor Es Ex CPU DSP A D Vin A Vin B...