iFLOW HVAC INC.

www.iflowhvac.com

1) Maintenance:

At the beginning of each season, the air handler should be serviced

by a qualified installer or service technician.

• Filter: This filter should be inspected and replaced as required.

• Coils: the heating and air conditioning coils should not require

regular maintenance IF a regular filter maintenance schedule is

followed. In the event, the filter is damaged or plugged and dust

has fouled the coil, replace the filter and carefully vacuum the

heating and/or A/C coil.

• Circulator: The circulating pump is water lubricated and should

not require regular maintenance. The system control has a pump

exercise function during prolonged periods of no heat to avoid

seizing.

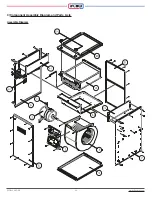

• Blower: The blower requires regular cleaning due to the build-up

of dust. In the event the filter is damaged, refer page 52 ~ 53 for

disassembly.

2) Checking Temperature Sensors:

1. Remove cables from the temperature sensor.

2. Check the sensor resistance and compare the actual values with

the curve on the chart.

3. Replacement of a sensor is required in the case of severe

deviation.

Water Temp. Sensor Chart

Resis

tance

Service and Maintenance

Evap. Temperature Sensor

Resis

tance

Resis

tance

Temperature

Outdoor Temp. Sensor Chart

22

Summary of Contents for iFLH-14000W

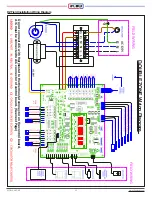

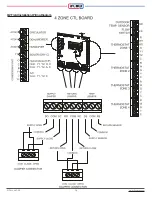

Page 24: ...iFLOW HVAC INC www iflowhvac com SZ Field Installation Wiring Diagram 24 See Details Page 29...

Page 26: ...iFLOW HVAC INC www iflowhvac com DZ Field Installation Wiring Diagram 26 See Details Page 29...

Page 28: ...iFLOW HVAC INC www iflowhvac com QZ Field Installation Wiring Diagram 28...

Page 30: ...iFLOW HVAC INC www iflowhvac com 4 Ladder Diagram 30...

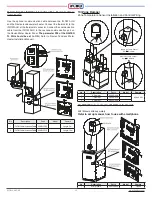

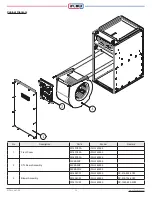

Page 43: ...iFLOW HVAC INC www iflowhvac com 43 Installation on the wall...