2

1 Function and features

The flow monitor monitors liquid media. It senses whether there is a preset flow

and provides a switching signal.

•

The switch point can be set: 10...60 cm/s in steps of 5 cm/s). This value is valid

for water and installation in pipes 4". It changes with other media/other pipe

diameters.

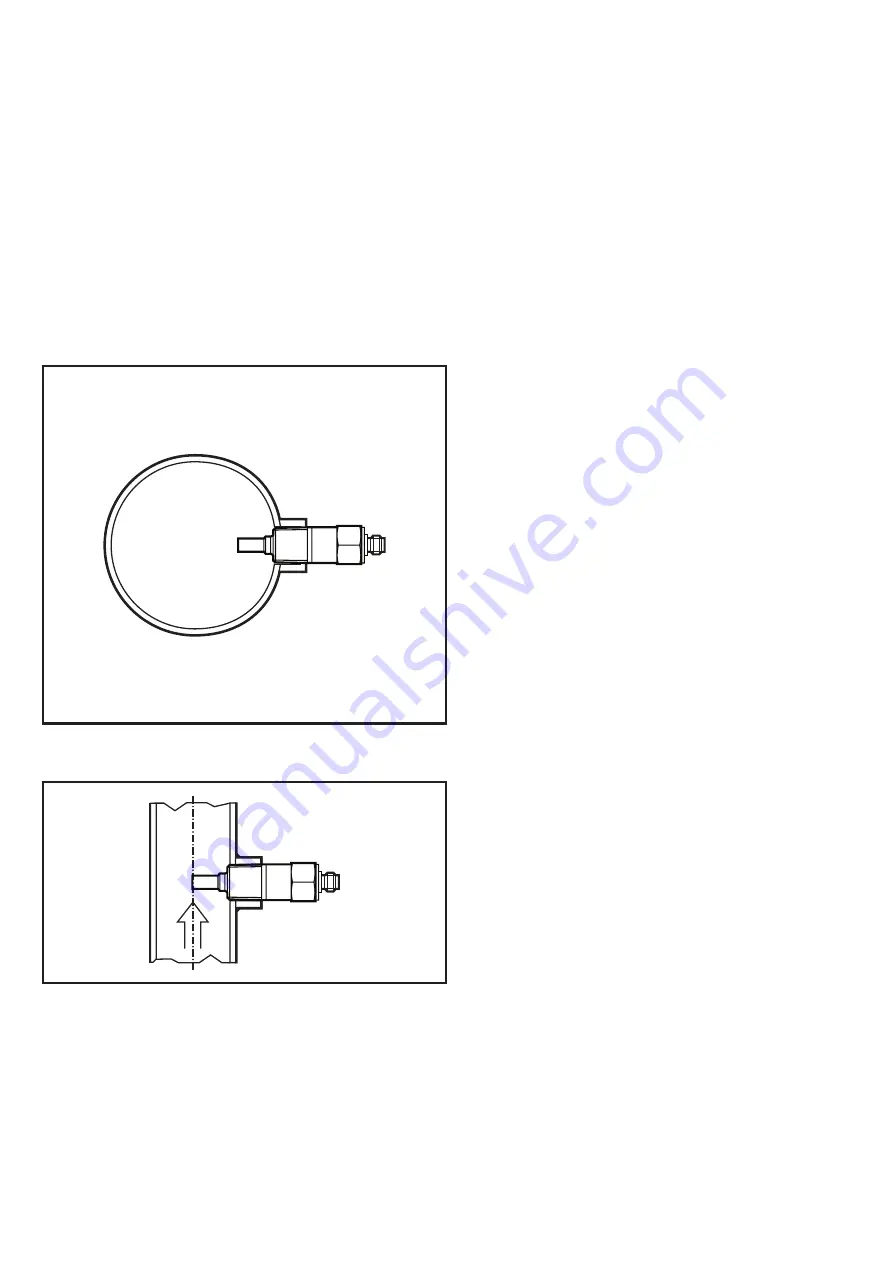

2 Installation

The sensor tip must be completely immersed in the medium.

►

In the case of horizontal pipes

mount the unit from the side, if

possible.

•

When the unit is to be mounted at

the bottom of the pipe, it should

be free from deposits.

•

When the unit is to be mounted

at the top of the pipe, it should be

completely filled with the medium

to be monitored.

►

In the case of vertical pipes mount

the unit in a place where the

medium flows upwards.

Use only a correctly-sized spanner (or torque wrench) to fasten the unit.

Tightening torque max. 100 Nm (with stainless steel adapter) or ANSI B1.20.1.