3

UK

1 Preliminary note

•

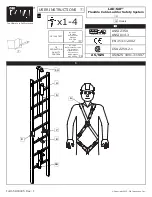

An instruction is indicated by "►":

Example: ► Mount the unit as shown.

Important note

Non-compliance may result in malfunction or interference�

Information

Supplementary note

2 Safety instructions

• Please read the operating instructions prior to set-up of the unit� Ensure that

the product is suitable for your application without any restrictions�

• The unit conforms to the relevant regulations and EC directives�

• Improper or non-intended use may lead to malfunctions of the unit or to unwan-

ted effects in your application�

• Installation, electrical connection, set-up, operation and maintenance of the unit

must be carried out by qualified personnel authorised by the machine operator�

• The design of the unit corresponds to protection class III (EN61010) except for

the terminal blocks� Protection against accidental contact (safety from finger

contact to IP 20) for qualified personnel is only ensured if the terminals have

been completely inserted� Therefore the unit must always be mounted in a

control cabinet of at least IP 54 which can only be opened using a tool�

• For DC units the external 24 V DC supply must be generated and supplied

according to the requirements for safe extra-low voltage (SELV) since this vol-

tage is provided near the operating elements and at the terminals for the supply

of sensors without further protection measures�

3 Functions and features

• The diagnostic electronics has 2 analogue inputs and 4 dynamic inputs� These

inputs can be used for process value monitoring, vibration monitoring, vibration

diagnostics or analysis of other dynamic signals�

• An analogue current signal or a pulse signal can be connected to the analogue

inputs� They can be used as speed input for vibration diagnostics, as trigger of

a measurement or for process value monitoring�