5

UK

•

In case of malfunction of the unit please contact the manufacturer� Tampering

with the unit is not allowed�

•

Disconnect the unit externally before handling it� Also disconnect any

independently supplied relay load circuits�

•

After setup the system has to be subjected to a complete function check�

• Only use the unit under the specified operating conditions (→ 10 Technical

data)� In case of special operating conditions please contact the manufacturer�

• Use only as described below (→ 4).

Summary of Contents for G1501S

Page 1: ...706199 00 04 2012 Original operating instructions Safety relay with relay outputs G1501S UK ...

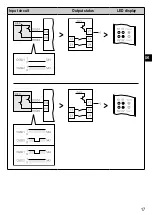

Page 16: ...16 Input circuit Output status LED display ...

Page 17: ...17 UK Input circuit Output status LED display ...

Page 26: ...26 LED display Cause of the fault Troubleshooting Short circuits Check wiring ...

Page 34: ...34 8 4 2 Function Input circuit Output status LED display N O contact activated ...

Page 44: ...44 LED display Cause of the fault Troubleshooting Short circuits Check wiring ...

Page 49: ...49 UK ...