14

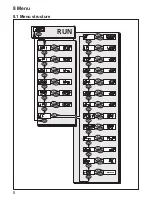

10 Operation

After power on, the unit is in the Run mode (= normal operating mode) It carries

out its measurement and evaluation functions and provides output signals accord-

ing to the set parameters

Operating indications → Chapter 7 Operating and display elements.

10.1 Reading of the set parameters

Press [Mode/Enter] until the requested parameter is displayed

►

Press [Set] briefly

►

The unit displays the corresponding parameter value for about 15 s After

>

another 15 s the unit returns to the Run mode

10.2 Fault indication

[OL]

Temperature too high (measuring range exceeded by more than 3% of the final

value of the measuring range)

[UL]

Temperature too low (measuring range below the final value of the measuring

range by more than 10%)

[Err]

No temperature sensor connected

•

Fault or short circuit in the temperature sensor, wire break

•

Detection zone is exceeded (T < -60°C or T > +160°C)

•

[SC1]

Short circuit in OUT1*

[SC2]

Short circuit in OUT2*

[SC]

Short circuit in both switching outputs*

[Loc]

Setting pushbuttons of the unit locked, parameter change rejected

[SLoc] Unit locked via software, parameter change rejected

[PARA]

Setting value of a parameter outside the valid range → the unit is not ready for

operation The error may occur with IO-Link parameter setting

If an invalidly set parameter is activated, [PARA] is displayed instead of the

parameter value

*The output concerned is switched off as long as the short circuit exists

The messages Err, PARA and SC1 are shown even if the display is switched off