220

ifm

Programming Manual BasicController relay CR0431 v03.03.00

05 / 2018

Terms and abbreviations

>

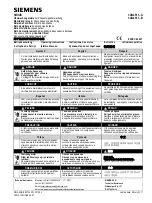

Pictogram

Pictograms are figurative symbols which convey information by a simplified graphic representation.

(

→ chapter

What do the symbols and formats mean?

(

>

PID controller

The PID controller (proportional

–integral–derivative controller) consists of the following parts:

• P = proportional part

• I = integral part

• D = differential part (but not for the controller CR04nn, CR253n).

>

PLC configuration

Part of the CODESYS user interface.

► The programmer tells the programming system which hardware is to be programmed.

>

CODESYS loads the corresponding libraries.

>

Reading and writing the periphery states (inputs/outputs) is possible.

>

Pre-Op

Pre-Op = PRE-OPERATIONAL mode.

Operating status of a CANopen participant. After application of the supply voltage each participant

automatically passes into this state. In the CANopen network only

→SDOs and →NMT commands

can be transferred in this mode but no process data.

>

Process image

Process image is the status of the inputs and outputs the PLC operates with within one

→cycle.

At the beginning of the cycle the PLC reads the conditions of all inputs into the process image.

During the cycle the PLC cannot detect changes to the inputs.

During the cycle the outputs are only changed virtually (in the process image).

At the end of the cycle the PLC writes the virtual output states to the real outputs.

>

PWM

PWM = pulse width modulation

The PWM output signal is a pulsed signal between GND and supply voltage.

Within a defined period (PWM frequency) the mark-to-space ratio is varied. Depending on the

mark-to-space ratio, the connected load determines the corresponding RMS current.

>

R

ratiometric

Measurements can also be performed ratiometrically. If the output signal of a sensor is proportional to

its suppy voltage then via ratiometric measurement (= measurement proportional to the supply) the

influence of the supply's fluctuation can be reduced, in ideal case it can be eliminated.

→ analogue input

>

RAW-CAN

RAW-CAN means the pure CAN protocol which works without an additional communication protocol

on the CAN bus (on ISO/OSI layer 2). The CAN protocol is international defined according to

ISO 11898-1 and garantees in ISO 16845 the interchangeability of CAN chips in addition.

Summary of Contents for BasicController CR0431

Page 228: ...228 10 Notizen Notes Notes...