24

11 Maintenance

►

Keep the process connection free of deposits and foreign bodies�

►

In case of heavy soiling: clean the process connection and the probe at regular

intervals�

In case of longer operation separation layers can form in the medium (e�g� oil on

water)� This applies especially to still pipes or bypasses�

►

Remove separation layers at regular intervals�

►

Ensure that the vent hole (at the upper end of the coaxial pipe) remains free�

►

Keep the interior of the coaxial pipe free from foreign bodies and soiling�

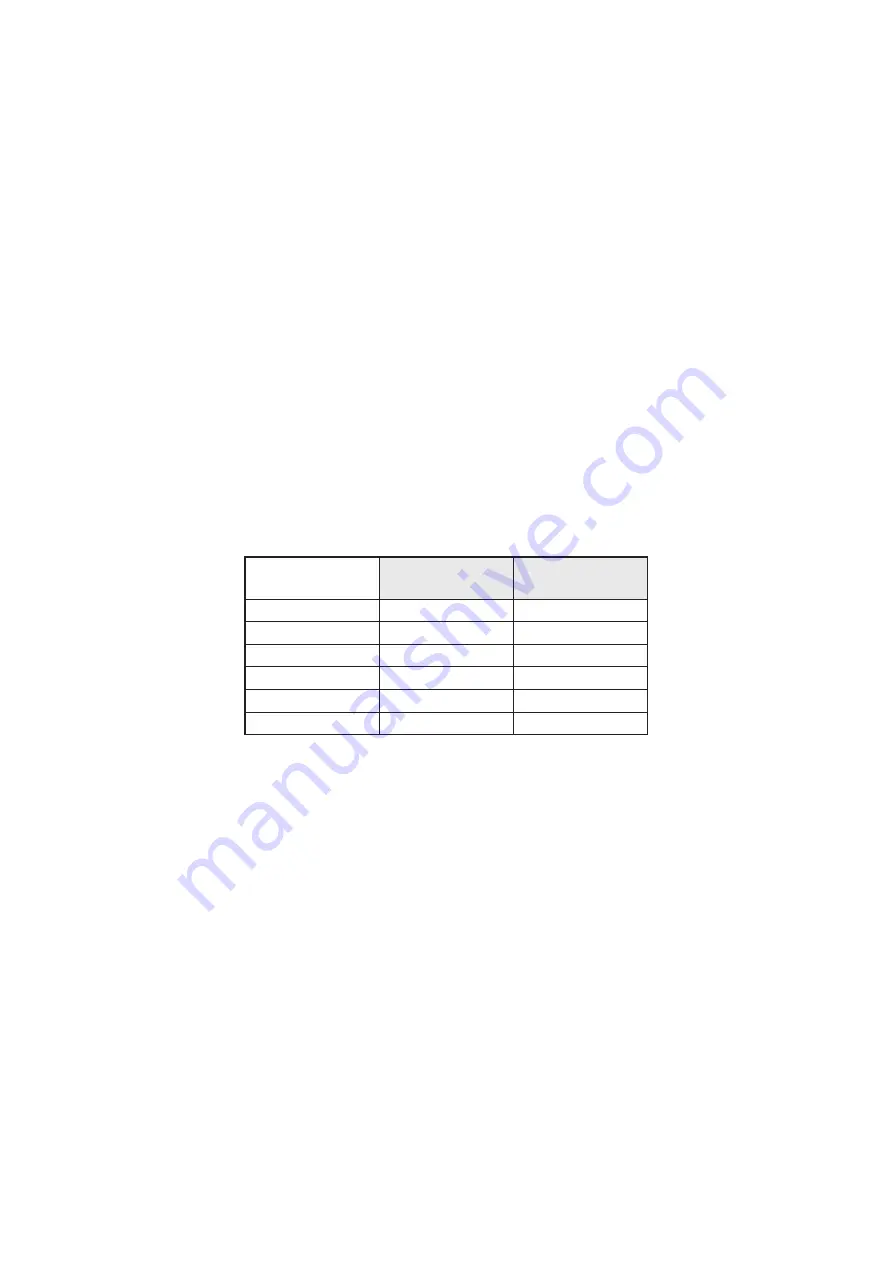

12 Factory setting

(Special units LXxxxx*

)

not taken into account)

Factory setting

LR9020

User setting

OU2

I

FOU2

OFF

dFo

0

LEnG

450

MEdI

HIGH

Prob

rod

*

)

Settings of the special units LXxxxx → Technical data sheet.