10

Tipping Trailers

Operator Manual

HYDRAULIC SYSTEM MAINTENANCE

1.

Wipe all external surfaces of the pump and reservoir tank to

remove dirt, dust and oil residue.

2.

Inspect unit for leaks and rectify as necessary.

3.

Clean reservoir filler cap, remove and renew if cap and / or seal

is damaged. Check oil level and replenish with clean hydraulic

oil.* This should preferably be carried out with actuator (and

thus the body ram) at minimum stroke, i.e. with the trailer body

down. The oil should be approximately 25mm (1”) from the top

of the reservoir tank when full.

4.

Fully replace the hydraulic oil at intervals depending upon the

severity of the duty and environment conditions:

Very dirty, dusty and damp:

6 months to 1 year.

Otherwise, in more favourable conditions: Approx. 2 yearly.

Draining the Tank

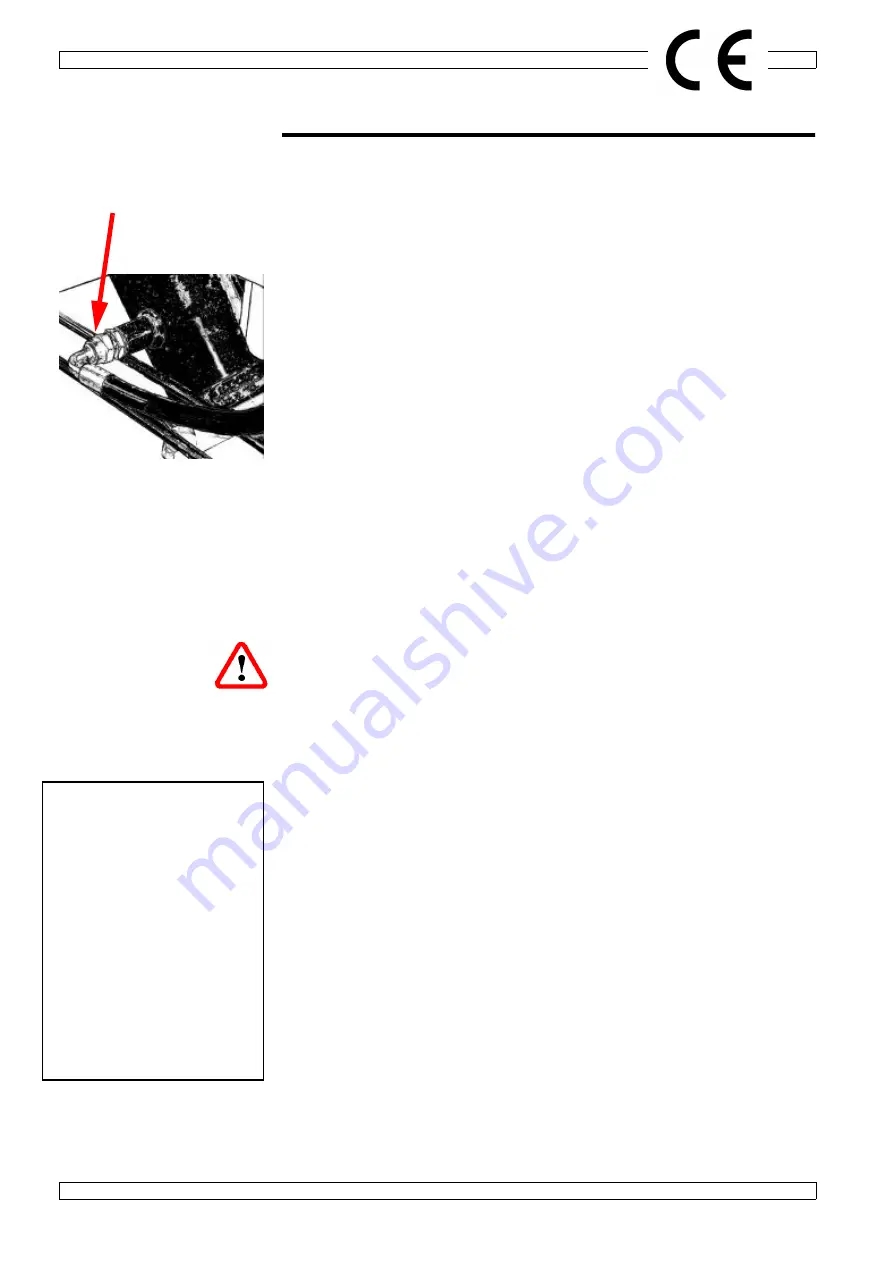

With the body fully lowered, remove the main pressure supply hose

from the ram (fig 15) and dip into a suitably sized and positioned

container or oil drum. Switch on the electrical operating system (or

operate the manual pump) to pump the oil into the container.

Continue until the oil flow virtually ceases.

DO NOT RUN THE PUMP FOR LONGER

THAN IS NECESSARY WHEN THE TANK

IS APPROACHING EMPTY

Filling the Tank

Use clean, filtered oil of the correct grade. Use a filter unit with a

filtration level of 25 microns (25 µm) or better.

Use only clean jugs and funnels.

CONTAMINATION OF HYDRAULIC OIL ACCOUNTS FOR THE

VAST MAJORITY OF HYDRAULIC SYSTEM FAILURES

Connect the hose to the ram but do not tighten.

Fill the tank to the level mark.

Bleed the system by operating the motor briefly (or operate the

manual pump) whilst observing the release of air from the hose

connection on the ram. As soon as there is no sign of air escaping,

tighten the connector. Check the oil level and top up if necessary.

Main hydraulic

pressure supply

hose connector

* Oil Specification for the

Fenner / SPX Power Pack

Fenner recommend

SHELL TELLUS 37

or it’s equivalent for

temperatures between -

18

o

C

and +70

o

C

. This

should cover most normal

applications.

See pages 11 & 12 for

appropriate graphs

Fig.15