An alarm condition was

observed on the display. The

keys were inactive.

• Any of

the safety elements on the stove may have

been activated.

•

Overheating

• Exce

ssive water pressure

• Fuel

may be exhausted.

• Door

open

• Ignition failed.

• Refer to the code of the al

arm status and a

description of the code in the instruction manual.

• Ke

ep the on / off button pressed so that the stove

is self-controlled. If the fault is cleared, the stove

switches to the shutdown state. If the alarm

continues, the error continues.

• I

n case of overtemperature, turn the stove to off

and allow it to cool down. Then re-ignition.

• Reduce the pressure to less t

han 2 bar by

discharging water from the installation.

• Fill the fu

el tank.

•

Make sure the door is closed.

• After waiting for you

r stove to shut down, clean

the burner and re-ignition.

Oven does not heat up

• The smoke flap is in the wrong direction.

• The s

tove may not have entered the powers.

•

The stove is switched off.

• Fue

l may be exhausted.

• The direction of the flap should

be to the left.

• Wait for the stove to pa

ss.

• Re

-ignite if the stove is switched off.

• Load fuel.

Oven is very hot

• Not at t

he desired power setting.

• Set the desi

red temperature using the flame

configurations from the control panel.

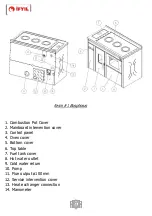

Summary of Contents for BOSPHORUS

Page 2: ...1...

Page 25: ...24 8 TEMEL PAR ALAR VE BOYUTLAR Model Galata...

Page 27: ...9 BA LANTI EMALARI 9 1 Anakart...

Page 61: ...60 8 MAIN PARTS AND DIMENSIONS Model Bosphorus...