REFRIGERATION LTD

Pastry Display Cases

| www.igloorefrigeration.com

13

Do not use mechanical agents to quicken the defrosting process!

It is recommended to make a break in the operation once a month in order to clean the interior, naturally defrost

the evaporator and clean the condenser, and evaluate the condition for door seal (CURP2)

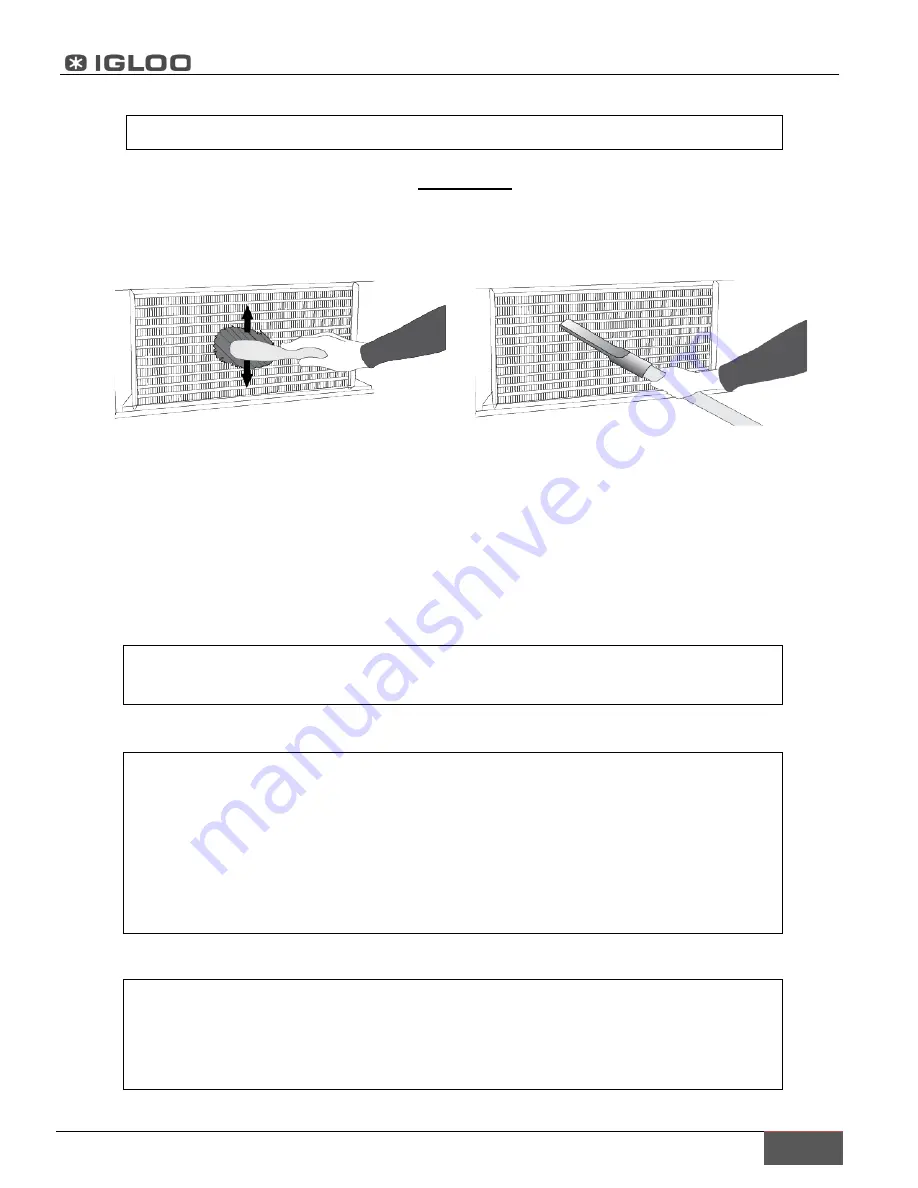

It is essential to keep the condenser of the device clean. Dirt may hinder the heat exchange, causing mainly an

increase in electric energy consumption and may cause damage of the compressor. In order to clean the

condenser it is necessary to unscrew the sheet metal screws and pull the wind brace out of catch by lifting it up.

Clean condenser lamellas with help of soft brush or paint brush. If the condenser is extremely dirty (blocking of

lamellas) it is indicated to use vacuum cleaner or compressed nitrogen to suck / blow the dirt from between

lamellas.

The seller shall not be held responsible for any condenser damages in the case of non-

observance of condenser cleaning instructions

(This concerns

CURP2, CURLP2, and CURHP2) Door seal should be cleaned solely with

clean water without any cleansing agents and it should be thoroughly dried.

The seal

cannot get into contact with oily substances or grease! Ensure door closed properly

during maintenance procedures.

Test: place a sheet of paper between the seal and the casing and close the door. The

paper should pose a tangible resistance during an attempt to pull it out.

Elements of equipment can corrode as result of improper use and maintenance. To

prevent damage: Do not allow contact of the with substances containing chlorine and/

or baking soda in different varieties, which destroy the protective layer and components

of the equipment (also includes various stainless steel)

Figure 8 Cleaning the condenser