REFRIGERATION LTD

Pastry Display Cases

| www.igloorefrigeration.com

9

4.1. Temperature regulation

The thermostat is to obtain the set temperature within the equipment and maintain it within the determined

temperature ranges. The manufacturer enters all settings of temperature regulators required for normal

functioning of the equipment. Before primary actuation the user should control and possibly set the required

temperature inside the equipment on the control panel.

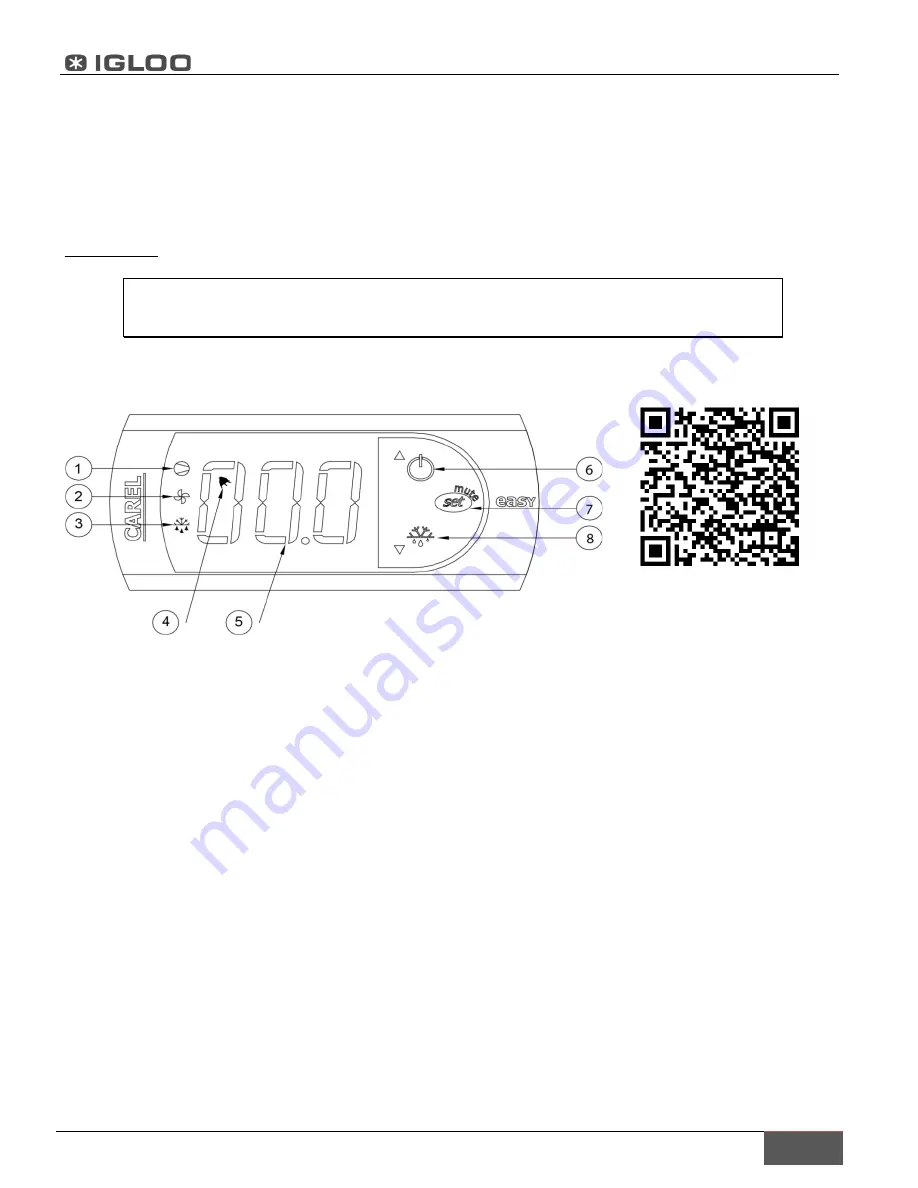

Digital display – displays the current temperature inside the equipment.

It is forbidden to interfere with systemic parameters of the thermostat, as this can

lead to serious consequences, including the damage of the cooling unit!

WHAT DO DIODES ON CONTROL PANEL SIGNIFY

Diode 1 - Compressor: This symbol is visible when the compressor is working. It blinks when compressor actuation

is delayed by security procedure. It blinks in the following cycle: two blinks – pause, when the constant

working mode is activated.

Diode 2 - Ventilator: This symbol is visible when evaporator ventilators are turned on. It blinks when the actuation

of the ventilators is delayed by external disengagement or when another procedure is in progress.

Diode 3 - Defrosting: This symbol is visible when the defrosting function is activated. It blinks when the actuation is

delayed by external disengagement or when another procedure is in progress.

Diode 4 - Alarm: This symbol is visible when the alarm is activated.

Diode 5 - Current temperature: inside the equipment is displayed (decimal places displayed after the comma).

Diode 6 – On/Off Switch: Pressing this button alone: for more than 3 sec. switch On/Off, Pressing with other

buttons: pressed together with 8 activities/deactivates the continuous cycle.

Diode 7 – Set/ Mute: Pressing this button alone: 1 sec. displays /sets the set point, more than 3 sec. accesses the

parameter setting menu (enter password 22), mutes the audible alarm (buzzer), Start Up: hold the set/mute button

for 1 sec. RESET current EY set / Pressed together (7 and 8) activate parameter reset procedure.

Diode 8 – Defrost: Pressing this button alone: more than 3 sec. activates/deactivates the defrost. Pressing with

other buttons: pressed together with 6 activates/deactivates the continuous cycle, Start Up: hold for 1 sec. displays

firmware version.

Figure 6 “Carel” thermostat control panel

QuickFinder for CAREL