REFRIGERATION LTD

Refrigerated Pastry Display Case

| www.igloorefrigeration.com

13

5. MAINTENANCE

Do not use steel wool, abrasive cleaners, bleach or cleaners containing chlorine or sodium to clean the unit.

Do not use pressure washer or water-jet to clean the unit.

The unit should be cleaned right after unpacking and before turning on.

The unit should be cleaned with warm water and mild soap.

Devices with wheels cannot be used on uneven surfaces!

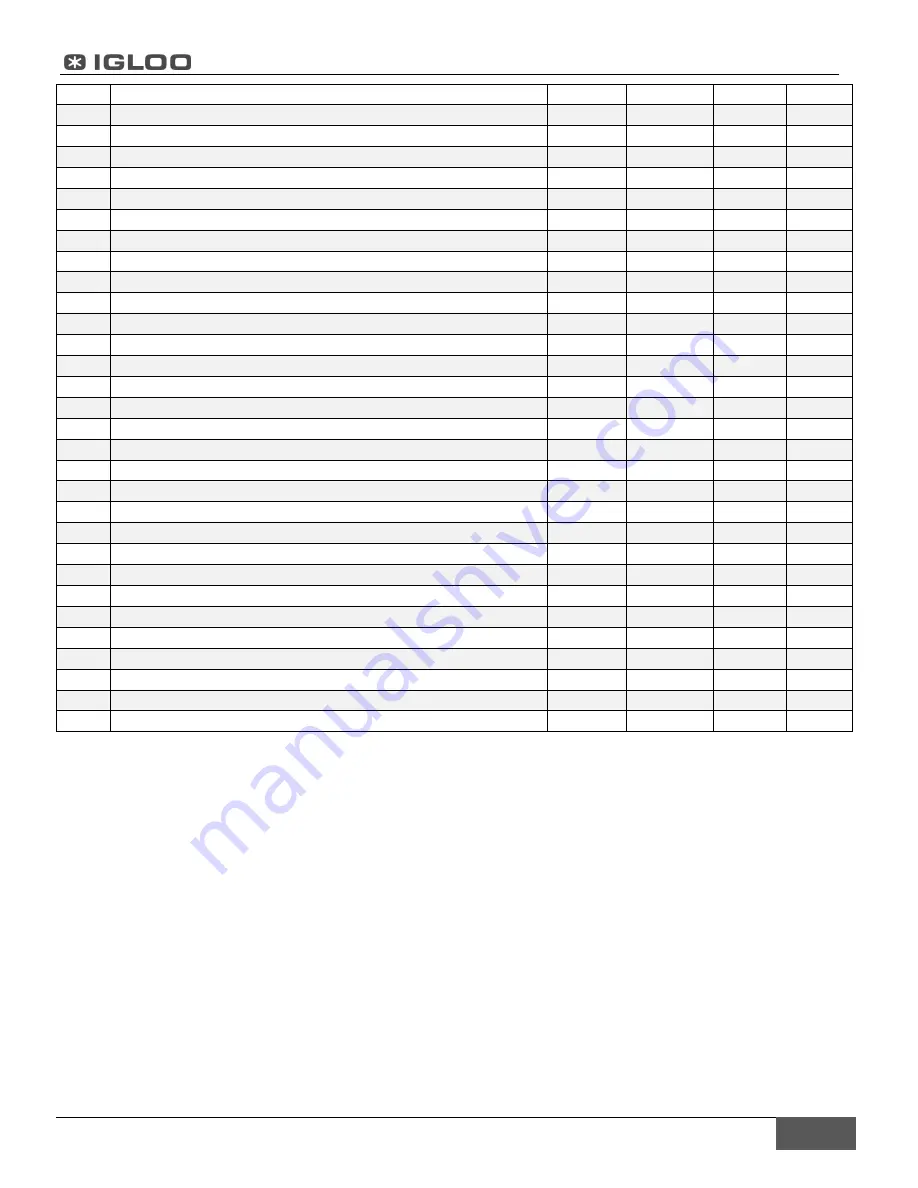

c4

compressor on time with duty setting

50

min

0

100

cc

continuous cycle duration

2

2

0

15

c6

temperature alarm bypass after continuous cycle

2

h

0

15

d0

type of defrost

0

-

0

4

dI

interval between defrosts

8

h

0

199

dt

end defrost temperature set point

12.0

°C

-50

130

dP

maximum defrost duration

60

min

1

199

d4

defrost when switching the instrument on

0

-

0

1

d5

defrost delay on power-up or when enabled by digital input

0

min

0

199

d6

freeze control temperature display during defrost

1

-

0

1

dd

dripping time

2

min

0

15

d8

alarm bypass time after defrost

1

h

0

15

d9

defrost priority over compressor protectors

0

-

0

1

d/

defrost probe reading (2)

-

°C

-

-

dC

time base

0

-

0

1

A0

alarm and fan temperature differential

2.0

°C

-20

+20

AL

absolute/relative temperature for low temperature alarm

0.0

°C

-50

+99

AH

absolute/relative temperature for high temperature alarm

0.0

°C

-50

+99

Ad

temperature alarm delay

0

min

0

199

A4

3rd input configuration

0

-

0

11

A7

digital input alarm delay

0

min

0

199

A8

enable alarm “Ed” (end defrost by timeout)

0

-

0

1

Ac

set point dirty condenser alarm

60

°C

-50

250

AE

dirty condenser alarm differential temperature

3.0

°C

0.1

20

Acd

dirty condenser alarm delay

0

min

0

250

H0

serial address

1

-

0

207

H1

AUX output configuration

0

-

0

2

H2

enable keypad

1

-

0

2

H4

disable buzzer

0

0

1

H5

ID code (read-only)

-1

-

1

+199

EZY

restore the Default settings

2

0

0

1