en

16

User manual Monika 2, Rota

www.igloo.pl

4.1. Temperature regulation

Service of “Igloo” and “Carel” thermostat (temperature regulators) is described in chapter 7 (p.19 and 20)

The basic aim of a thermostat is to control the cooling aggregate to obtain the set temperature within the device and

maintain it within the determined temperature ranges. The producer enters all settings of temperature regulators required

for normal functioning of the device. Before primary actuation the user should control and possibly set the required tem-

perature inside the device on the control panel.

Digital display – displays the current temperature inside the device.

It is forbidden to interfere with systemic parameters of the thermostat, as this can lead to serious consequ-

ences, including the damage of the cooling device!

5. MAINTENANCE

5.1. Cleaning and maintenance

All maintenance services need to be performed after disconnecting the device from power supply!

Protect electric installation against any damage or water spillage

Do not use water stream to clean the device, only a wet cloth

Do not use any sharp objects to remove

fi

lth!

Devices equipped with wheels cannot be used on uneven surfaces!

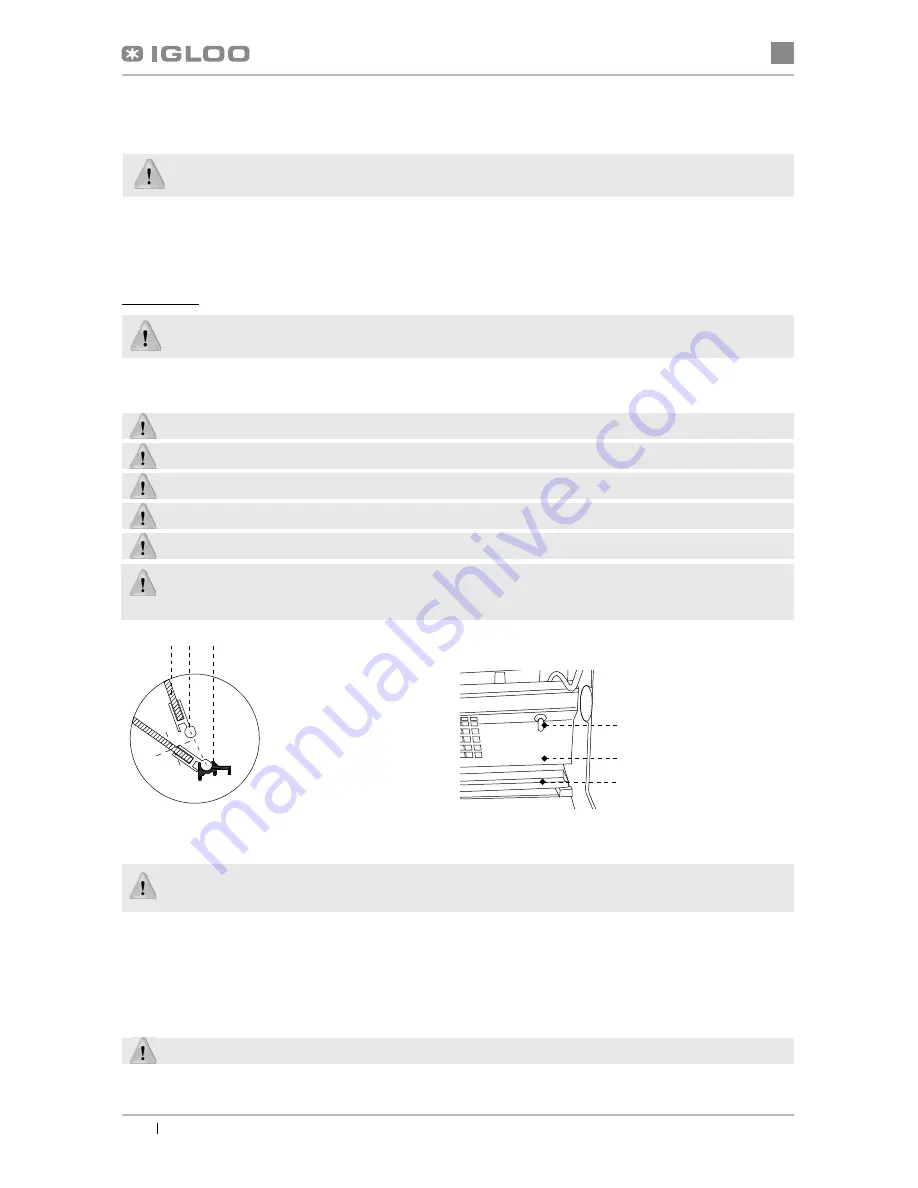

During cleaning the inside of the device do not leave the front glass freely lifted in the aluminium pro

fi

le. This may

cause the damage of the glass and is not covered by warranty. Please remove the glass with pro

fi

le for the time of

cleaning Fig.8 (p.16).

Fig.8 Front glass

disassembly

1- Front glass

2- Upper aluminium pro

fi

le

(lifted guide) of the glass

3- Lower aluminium pro

fi

le

(catch) of the glass

Fig.9 Temperature sensor

inside the device

1 – Temperature sensor

2 – Evaporator screen

3 – Evaporator drip rail

When using the display cabinet, as well as during maintenance works, pay attention not to destroy the tempe-

rature sensor in the evaporator screen!

It is recommended to make a break in the exploitation of the device once a month in order to clean its interior,

naturally defrost the evaporator, clean the condenser and verify the condition of door seals.

If the device is not equipped with automatic condensate evaporation, it is essential to remove the condensate from the

container when

fi

lling the container Fig.6 (p.15). The number (frequency) of condensate removal depends on device

exploitation conditions (f. ex. air humidity, door opening frequency, the amount and temperature of products placed for

storage).

Do not use mechanical agents in order to fasten the defrosting process!

3

2

1

1

2 3