en

17

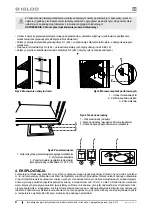

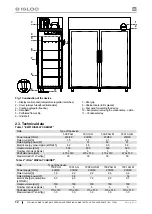

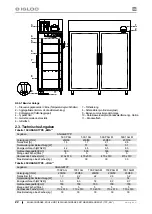

COOLING CABINETS, MEDIUM-FREEZING AND FREEZING CABINETS WITH UPPER AGGREGATE (“AG” TYPE)

www.igloo.pl

During maintenance services it is necessary to pay attention not to damage the data plate of the device

Fig.9 (p.18), which contains signi

fi

cant information for servicing organs and waste removal companies.

6. SERVICE

6.1. Fault identi

fi

cation and repair

In case of any dif

fi

culties during actuation of the device or during its exploitation, please return to these chapters in this ma-

nual, which explain the performed operation. This aims to ensure that the device is properly operated. If you still experience

dif

fi

culties, the following hints will help you solve the problem.

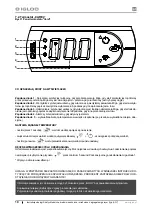

The device is not working... – Make sure that:

• The device is connected to the supply network

• Voltage and frequency in the network are compliant with those recommended by the producer 230V/50Hz.

• The main switch is turned on.

• The thermostat is turned on (Concerns the Igloo thermostat – If only two dots are displayed on the screen – turn on the

thermostat)

Water leakage from under the device or into inside of the chamber

• Verify the correctness of device levelling

• Verify the patency of outlet hoses

• Empty the condensate tray or container

The device is operating, the lighting is switched off... – Make sure that:

• The lighting switch is on

• Fluorescent lamp or the starter of the device are not burnt

The device does not reach the proper temperature, the lighting is on...– Make sure that:

• The main switch is turned on

• Temperature setting on the thermostat is properly set

• The thermostat is operating properly

• Make sure that the condenser is not

fi

lthy, and clean the condenser when necessary

• Ambient temperature does not exceed 25ºC

• Enough time has passed for products to be cooled

• Too much fresh food has been placed in the cabinet and the maximum freezing capability has not been exceeded

• Door of the devices close properly and whether the seal adheres to the body of the device

• Ventilation holes of the device are not blocked

(This concerns the “IGLOO” thermostat) thermostat displays C0 or C1 or C2 instead of displaying temperature:

This situation shall occur, when one of temperature regulation sensors has been destroyed.

The following messages may be displayed in such case:

• C0 – temperature sensors inside the chamber are damaged – call authorized service

• C1 – failure of evaporator sensor - call authorized service

• C2 – failure of condenser alarm sensors (or failure of second evaporator sensor) – call authorized service

(This concerns the “CAREL” thermostat) Thermostat displays E0 or E1 or L0 or HI or EE or Ed or DF instead

of temperature:

• E0 – failure of temperature sensor inside the chamber – call authorized service

• E1 – failure of evaporator sensor – call authorized service

• L0 – low temperature alarm (lower than temperature range set within the device – call authorized service

• HI – high temperature alarm – call authorized service

• EE – internal defect of the regulator – call authorized service

• Ed – max. defrosting time exceeded

• DF – defrosting in progress (this is not an alarm signal)

Elements of device can corrode when improper used and maintenance. To avoid that please

follow the rules:

• Do not allow contact of the surface of the device with substances containing chlorine and / or baking

soda in different varieties, which destroy the protective layer and components of the device (also

includes various stainless steel)