www.igmtools.com

5

Operating instructions EN

www.igmtools.com

4.2 Technical data

Input power

855W / 230V

Tape thickness

0,4 - 3mm

Tape thickness

10 - 65mm

Temperature range

120° - 200°C

Feed speed

4m/min

Shipping size

33,5x29,8x36,7cm

Weight

8,7kg

Shipping weight

11kg

Warm-up time(120 °C)

4min

Fuse

F 6A (230V)

Cable length

5m

Glue pot capacity

400ml

4.3 ContentsIGM

BR300 Portable

Edgebander for ABS

IGM Worktable Light

transport case

Sample tape from calibration procedures

5. TRANSPORT, UNPACKING AND ASSEMBLY

5.1 Transport and unpacking

The machine is not assembled due to transport.

Assemble before operating. Remove the edgebander

from the packaging and place on a flat surface. Check

for any apparent transport damages, these could

damage the machine or your health.

5.2 Assembly

5.2.1 Mounting the corner guide

- Equip the corner guide only when banding inner

corners or a radius smaller than 50 mm. It would be

getting in your way during other operations.

- Place the corner guide on your edgebander

according to pic.5 and tighten the screw.

Obr. 8

pic.1

6. SET-UP AND ADJUSTMENT

6.1 Preparing for work

6.1.1 How to measure and set up tape width

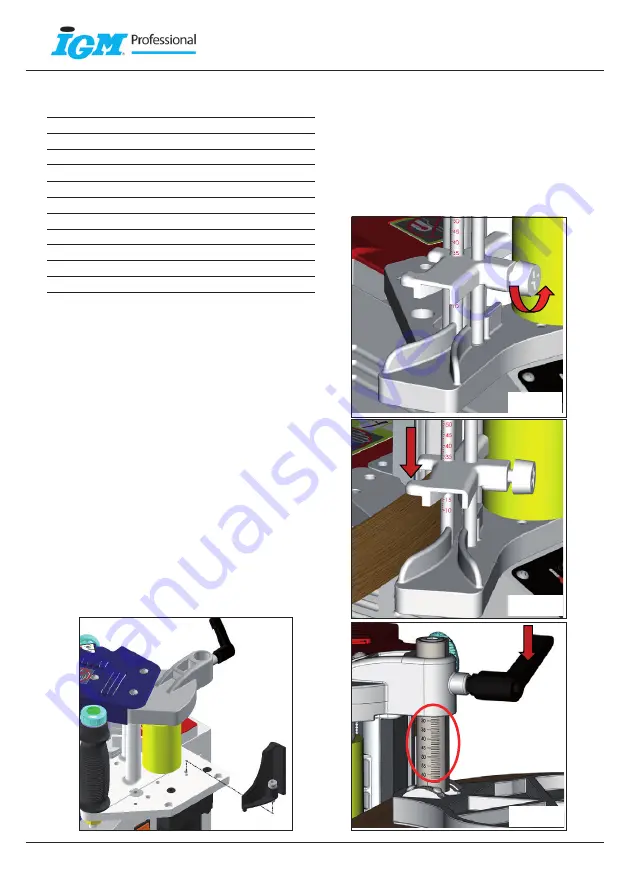

- Loosen the screw on the tape stop (pic.2)

- Place the tape under the stop and measure the

height (pic.3), tighten the screw.

- Measure the thickness of the banded piece and

set up the support table accordingly, make sure to

tighten the locking lever properly (pic.4)

Fig1

pic. 2

Fig3

333

pic. 4

Fig2

pic. 3