16

ACC-SVN190B-EN

discharge pressure at the selected setpoint anytime the

compressor is operating.

Set Pressure Setpoint

The pressure setpoint should be adjusted to 250 psig

initially. When the ambient temperature is above 50°F

(10°C), the outdoor fan motor will be energized

continuously. When the ambient temperature is below

50°F, the pressure sensor reading is used to switch the

motor on or off. When the pressure is 15psi below the

set pressure the motor will be turned off. When the

pressure is 15psi above the set pressure, the motor will

be turned on.

After completion of installation and pressure setting

adjustment), reinstall the compressor and control box

access panels and secure with screws that were

removed.

Reconnect all power to the unit. Refer to

troubleshooting guide, if needed.

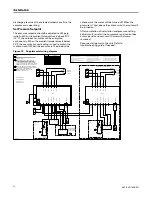

Figure 18.

Supplemental wiring diagram

DEV DES

DESCRIPTION

LAT1

AMBIENT TEMPERATURE 1

LAT2

AMBIENT TEMPERATURE 2

LOAM 1

LOW AMBIENT MODULE 1

LOAM 2

LOW AMBIENT MODULE 2

OFC1

OUTDOOR FAN CONTACTOR 1

OFC2

OUTDOOR FAN CONTACTOR 2

XDCR1

PRESSURE TRANSDUCER #1

XDCR2

PRESSURE TRANSDUCER #2

W

HITE

WHITE

RED

RED

BLACK

BLAC

K

BRO

WN

B

ROWN

BRO

WN

BROW

N

YELLOW

YELLOW

BROWN

BROWN

ORANGE

O

R

ANGE

BR

OWN

BROWN

O

R

ANGE

ORANGE

YELLOW

YELLOW

WHITE

WHITE

RED

RED

BLAC

K

BLACK

O

R

ANGE

ORANGE

B

LACK

RED

B

L

A

CK

ORAN

GE

BLU

E

BROWN

B

ROWN

BROWN

B

ROWN

W

HITE

WH

IT

E

R

ED

RED

BLACK

B

LACK

YELLOW

YELLOW

BROWN

BROWN

ORANGE

OR

ANGE

BROWN

BROWN

ORA

NG

E

ORANGE

YELLOW

YELLOW

RED

R

ED

BLACK, BLACK

BLACK

ORANGE

ORA

NGE

BLACK

RED

RED

BLAC

K

BLACK

GREEN

USE COPPER CONDUCTORS ONLY!

UNIT TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS.

FAILURE TO DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT.

CAUTION

¡UTILICE ÚNICAMENTE CONDUCTORES DE COBRE!

LAS TERMINALES DE LA UNIDAD NO ESTÁN DISEÑADAS

PARA ACEPTAR OTROS TIPOS DE CONDUCTORES.

SI NO LO HACE, PUEDE OCASIONAR DAÑO AL EQUIPO.

N'UTILISER QUE DES CONDUCTEURS EN CUIVRE!

LES BORNES DE L'UNITÉ NE SONT PAS CONÇUES

POUR RECEVOIR D'AUTRES TYPES DE CONDUCTEURS.

L'UTILISATION DE TOUT AUTRE CONDUCTEUR PEUT

ENDOMMAGER L'ÉQUIPEMENT.

PRECAUCIÓN

ATTENTION

LOW AMBIENT KIT FOR 2ND CIRCUIT

12133356-B

TO

OUTDOOR

FAN MOTOR

1 HARNESS

TO

OUTDOOR

FAN MOTOR

2 HARNESS

FACTORY SETTINGS:

CUT OUT SPEED - MIN

HARD START - MIN

SETPOINT - 250 PSIG

HEAT PUMP

ONLY

HEAT PUMP

ONLY

FACTORY

WIRES

FACTORY

WIRES

CONNECTIONS FOR

DUAL TRANSDUCERS

ON SINGLE MODULE

NOTES:

JUMPER DEFAULT POSITION IS ON N.O. FOR COOLING

ONLY UNITS, MOVE JUMPER TO N.C. POSITION FOR

HEAT PUMP UNITS

REMOVE BLACK FACTORY WIRE FROM SOV1, AND

BLUE FACTORY WIRE FROM SOV2. CONNECT THE

ORANGE WIRE/S FROM THE REV VALVE TERMINAL/S

TO SOV1 AND SOV2. CONNECT THE BLACK FACTORY

WIRE TO THE BLACK SUPPLIED WIRE IN LOAM1, AND THE

BLUE FACTORY WIRE TO THE BLACK SUPPLIED WIRE IN

LOAM2.

WHEN LOW AMBIENT KIT IS INSTALLED IN A SEPARATE

ENCLOSURE THEN TERMINATE THE GREEN WIRE IN THE

ENCLOSURE AND THE MAIN CONTROL BOX

CONNECTIONS FOR DUAL CIRCUIT ON ONE

MODULE WITH SINGLE FAN ONLY.

LAT1

L3

T3

L2

T2

L1

T1

OFC1

OUT

GND

IN

XDCR1

L

A

T2

L3

T3

L2

T2

L1

T1

OFC2

OUT

G

N

D

IN

XDC

R2

SOV1

S

O

V2

3

3

1

UC-P5

1

2

LOAM 1

T AMBIENT

C

Y1

Y2

REV

V

ALVE

P1 & P2 BLK

P1 & P2 RED

P1 B.W.G.

P

2

B.W

.G

.

LINE 1

L

OA

D 1

LINE 2

L

OA

D 2

LINE 3

L

OA

D 3

N.O.

HEAT

PUMP

N.C.

LOAM 2

T AMBIEN

T

C

Y1

Y2

REV

VALVE

P1 & P

2

B

L

K

P1 & P

2

RE

D

P1 B.W.

G

.

P2 B.W.

G

.

L

INE 1

LOAD

1

LIN

E 2

LOAD

2

LIN

E 3

LOAD

3

N.O.

HEAT

PUMP

N.C.

OUT

GND

IN

XDC

R2

1

1

2

2

2

4

4