-13-

www.igmtools.com

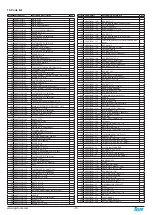

7. Troubleshooting guide

Machine does not start or a breaker trips.

Possible Cause

1. Power supply switched OFF or is faulty.

2. Wall fuse/circuit breaker is blown/tripped.

3. Faulty remote control.

4. Remote receiver is faulty.

5. Incorrectly wired motor connection.

6. On-board circuit breaker is tripped.

7. Wiring is open/has high resistance.

8. Faulty power switch.

9. Motor is at fault.

Possible Solution

1. Ensure power supply is ON and has the correct voltage.

2. Ensure adequate circuit size; install inlet restrictor, replace weak breaker.

3. Replace batteries; ensure unobstructed line-of-sight and signal range.

4. Inspect receiver circuit board; replace if faulty.

5. Rewire or call certified service technician or electrician.

6. Allow motor to cool, improve ventilation, press reset button.

7. Check for broken wires or poor connections, repair as necessary.

8. Replace switch.

9. Test/repair/replace.

Excessive vibration or noise during operation.

Possible Cause

1. Loose component.

2. Loose or broken motor mount.

3. Motor fan hitting fan cover.

4. Bad motor bearings.

Possible Solution

1. Inspect and tighten all bolts/nuts.

2. Tighten or replace as needed.

3. Check fan and cover; replace as needed.

4. Rotate shaft manually, check for grinding or loose shaft, replace bearings

if needed.

Loud, repetitive noise, or excessive vibration coming from

cyclone

Possible Cause

1. Machine is on uneven surface.

2. Damaged/Unbalanced impeller.

3. Loose connections.

4. Impeller is loose.

5. Motor fan hitting fan cover.

Possible Solution

1. Stabilize on a flat surface.

2. Inspect impeller for dents, bends, loose fins. Replace if needed.

3. Check and re-tighten all fasteners.

4. Replace the motor and impeller.

5. Check fan and cover; replace as needed.

Dust cyclone does not adequately collect dust or chips;

poor performance.

Possible Cause

1. Canister end cap is full.

2. Filter is dirty.

3. Restricted duct line.

4. Suction route is too long or has too many sharp bends.

5. Wet lumber is clogging ducts.

6. Leaks in the duct work or too many open ports.

7. Inadequate velocity in the main suction line.

8. Wrong size ducting/ports used.

Possible Solution

1. Empty canister end cap.

2. Clean filter.

3. Clean inlet splitter.

4. Move machine closer to the point of suction, and rerun ducts to eliminate

sharp bends.

5. Use lumber with less than 20% moisture content.

6. Repair all duct leaks and close any ports not being used.

7. Increase velocity by opening 1 or 2 more blast gates to different branch

lines.

8. Re-size and re-install ducts and fittings.

Sawdust being blown into the air from the dust cyclone.

Possible Cause

1. Band clamp or end cap is not secure.

2. Loose or damaged seals.

Possible Solution

1. Re-install ensuring a tight fit.

2. Replace seals and gaskets.