-6-

www.igmtools.com

MULTIPLE HAND HELD REMOTE SETUP

You can pair up to five (MAX) hand held remotes; however each hand

held remote needs to be setup individually following the programming

steps above.

If you setup a sixth hand held remote, it will override the first hand held

remote. If a seventh hand held remote is setup, it will override the second

hand held remote. And so on.

5. Assembly

5.1 Unpacking

Your 3HP Mobile Dust Cyclone comes packed in a single box. Before

attempting to assemble this machine, follow these directions for

unpacking:

1. Carefully cut the banding straps and remove them from the box.

2. Cut along the tape line at the top of the box.

3. Remove all parts from the top of the styrofoam and set aside.

4. Remove the styrofoam packing material from the top of the machine.

5. Carefully take out the machine components from the box and set aside.

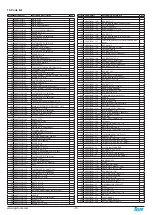

6. Using the diagram below, ensure that all parts are present and in good

condition.

Description

A. Motor

B. Remote cont Manual

C. Dust chute

D. Canister shield (front and back)

E. Top upright supports (3)

F. Canister cover plate

G. Drum insert (4)

H. HEPA Canister filter

I. Filter rotation shaft

J. Filter cleaning arm(2)

K. Crossbar

L. Collection bag for drum(3)

M. Cyclone funnel

N. Cyclone barrel

O. Intake cylinder

P. Octagon drum (front and back panel)

Q. Drum lid

R. Foot peddle bar

S. Filter end cap with 4” suction port

T. Octagon drum base panel

U. Lower upright supports (3)

V. Drum side plate (left and right)

W. Upright support reinforcement plate (3)

X. Foot peddle bar (left and right)

Y. Foot peddle assembly fittings

Y1. Lower triangular support plate (2)

Y2. Foot peddle bar support (2)

Y3. Lower support plate (2)

Z. Intake Reducer (8” by 6”) PFLUX2 only

AB. Intake adapter (8” by 4” x 3 ports) PFLUX3 only

AC. Autoclean plate

AD. Hardware box

Report any missing or damaged parts to your dealer or distributor. Prior to

tool assembly and use, read this manual thoroughly to familiarize yourself

with proper assembly, maintenance and safety procedures.

5.2 General Tool Assembly

This step requires two adults.

This 3HP Mobile Dust Cyclone is heavy,

be careful when lifting and handling it! Failure to comply may cause

serious injury and/or damage to the machine and/or property!

Tools Required

10 mm wrench / 12 mm wrench / 14 mm wrench

Phillips screwdriver. 4 mm hex wrench / 5 mm hex wrench

To assemble your dust cyclone, follow these steps:

For your own safety, do not connect the machine to the power source until

the machine is completely assembled. Please also make sure that you

read and understand the entire instruction manual.

ASSEMBLY TIME ESTIMATE 5-6 hours

Step 1: Remove the base which has been bolted to the (3) top upright

supports. Keep the (6) 3/8”x3/4” hex bolts and (6) 3/8” flat washers for

assembling the lower supports to the base. Keep the upper assembly

lifted for step 5.

Step 2: Turn base upside-down. Use (16) 5/16” x 3/4” hex bolts and (16)

5/16” flat washers. Attach the (2) 4” casters with brakes to the base. The

casters wit brakes should be attached to the side with the opening. The

remaining (2) 4” swivel casters must attach to the other end on the base.

Step 3: Turn the base over with it standing on the (4) 4” casters and

secure the three lower upright support panels using (6) 3/8” x 3/4” hex

bolts and (6) 3/8” x 7/8” flat washers..

A – shown with one dot is located on the canister side.

B – shown with two dots is located on the front side

C – shown with three dots is located on the opposite end.

Step 4. With the help of another person carefully lift the upper cyclone

assembly high enough to place on stands that you have completed in

steps 2 and 3. Take note on precisely positioning the upper cyclone

assembly onto the three lower upright supports. Using (6) 5/16” x 3/4” hex

bolts and (6) 5/16” flat washers connect and secure the upper and lower

upright supports.