-9-

www.igmtools.com

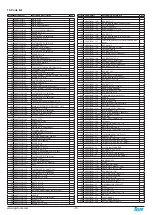

Step 23. Attach the two ends of the Octagon foot pedal to the nut on the

foot pedal bar.

Step 24. Secure the topping to the nut on the foot peddle bar using (1)

M8*30mm hex bolt. Follow this step on the opposite side.

Step 25. Secure the movable supporting brace on the foot peddle bar with

the octagon foot peddle using (2) 3/8”*21mm hex bolts. Make sure the bolt

head is on the inside of the octagon foot peddle. Adjust the tightness of

this bolt accordingly. If this bolt is too tight, the Octagon foot peddle will not

work smoothly. When too loose it will not pick up the Octagon drum.

Step 26. Secure the movable supporting brace on the foot peddle bar with

the octagon foot peddle using (2) 3/8”*21mm hex bolts. Make sure the bolt

head is on the inside of the octagon foot peddle. Adjust the tightness of

this bolt accordingly. If this bolt is too tight, the Octagon foot peddle will not

work smoothly. When too loose it will not pick up the Octagon drum.

Step 27. Apply foam tape to the cone flange before attaching the drum lid.

Secure the Octagon drum lid to the cyclone funnel using (6) 5/16” x 3/4”

hex bolts, (12) 5/16” x 1” flat washers and (6) 5/16” hex nuts. Make sure to

first attach all the bolts before tightening. NOTE: The lid will turn when the

bolts have not been tightened for alignment. Failure to do will result in the

drum lid not being able to align with the drum.

Step 28. Attach the full drum detection sensor to the opening on the drum

lid located behind the cyclone funnel. When securing the sensor make

sure the end of the sensor is not longer then the drum lid rim. If it extends

longer passed the rim, the detection will not function correctly.

Step 29. Attach the LED light to the drum lid using (6) M4*10mm Philip HD

Bolt, (6) 3/16” flat washers and (6) M4 hex nuts.

Step 30. Attach the crossbar to the drum lid and tighten using the two

bolts removed in the previous step. It does not matter which position you

attach the crossbar.

Step 31. Assemble the Octagon drum. Locate the drum base panel, (it

does not matter which side faces inside), and secure the (4) casters using

(16) 5/16” x 3/4” hex bolts, (32) 5/16” x 1” flat washers and (16) 5/16” hex

nuts.