-6-

www.igmtools.com

Pic. 18

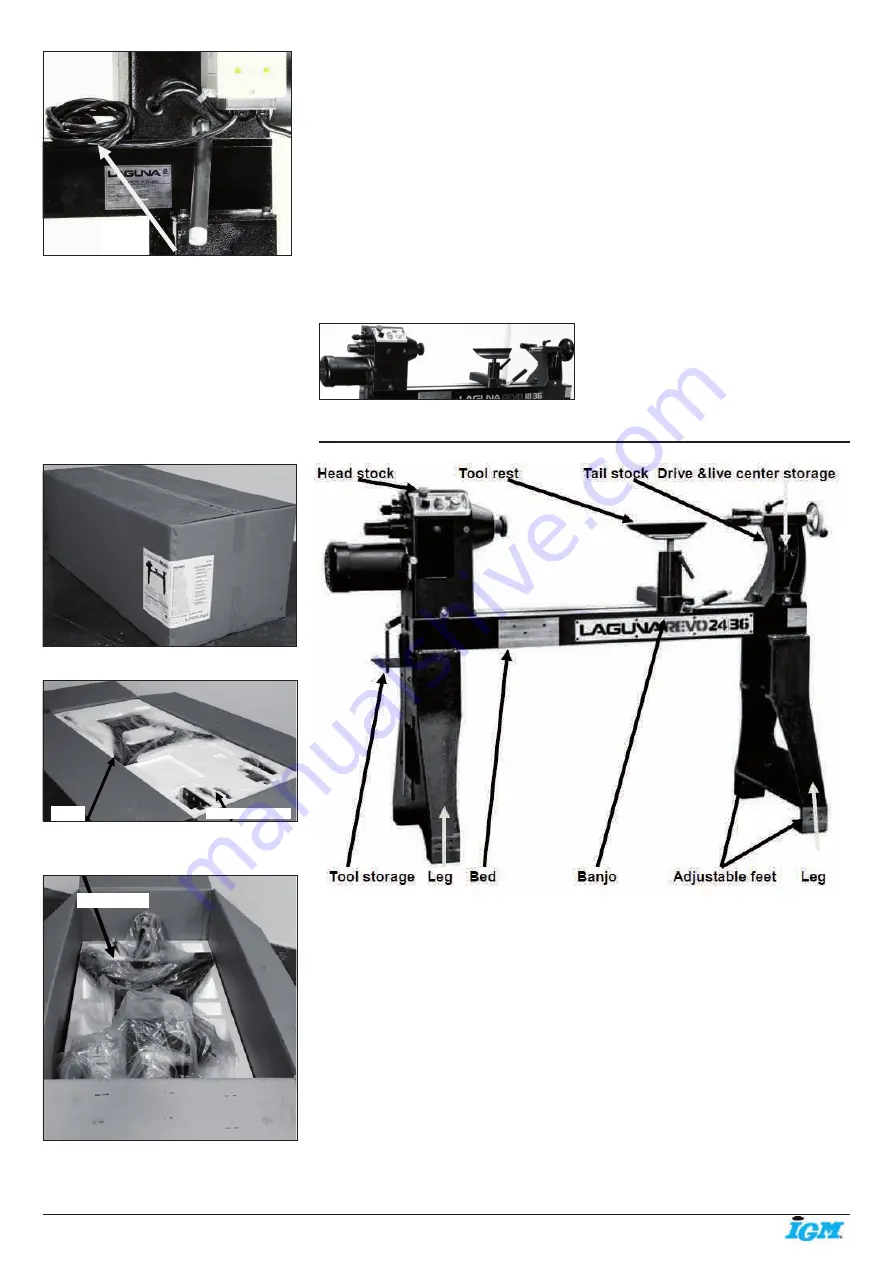

5. Receiving your machine

5.1 Unpacking and transport

To unpack your machine you will need tin snips,

a knife, and a wrench.

1. Using the tin snips, cut the banding that is

securing the packing box (If fitted).

Extreme caution must be used, because the

banding will spring and could cause injury.

Lathe in packaging

Pic. 19

Pic. 20

Top packaging removed

Pic. 21

2. Open the box and remove the parts sent with

the lathe including the first leg.

Note:

The legs are heavy and caution must be

exercised. They are cast iron and if dropped

they will break.

3. Remove the top packaging and remove the

second leg.

4. Remove the lathe bed. It is recommended

that it be lifted with a hoist or forklift using a

„sling“ as it is very heavy.

Note:

The machine is heavy. Ensure that you

have enough people to do the job safely. Do not

attempt any procedure that you feel is unsafe,

or that you do not have the physical capability

of achieving.

5. Lower the bed of the lathe onto 2 stacks of

wood. This will allow access to the underside of

the bed.

Pic. 22

5.2 Receiving the lathe

Before you unpack your new machine you will

need to first inspect the packing, invoice and

shipping documents supplied by the driver.

Insure that there is no visible damage to the

packing or the machine. You need to do this

prior to the driver leaving. All damage must be

noted on the delivery documents and signed

by you and the delivery driver. You must then

contact the seller (Laguna Tools) as soon as

practical. If damage is found after delivery,

contact the seller as soon as is practical.

Note:

It is probable that you will find sawdust

within your machine. This is because the

machine has been tested prior to shipment

from the factory. It must be noted that additional

machine movement can take place between

Laguna Tools and the end user and some

adjustments may have to be undertaken by the

customer. These adjustments are covered in

the various sections of this manual.

Parts of the lathe

Supplied with:

Leg

Parts

druhá noha

Power

cord

Second leg

Summary of Contents for LAGUNA 2436

Page 2: ...2 www igmtools com...

Page 12: ...12 www igmtools com Electrical drawing Wiring diagram for control panel on headstock...

Page 13: ...13 www igmtools com Exploded view drawings and parts list Wiring diagram for remote control...

Page 14: ...14 www igmtools com...

Page 20: ...20 www igmtools com...

Page 21: ...21 www igmtools com...