-9-

www.igmtools.com

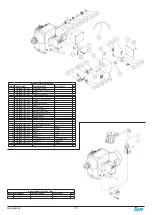

Pic. 45

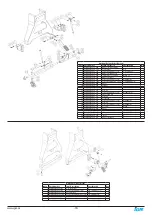

Head stock clamp lever.

The head stock clamp lever allows the head

stock to be released and moved to any position

on the lathe bed. It is located at the back of the

head stock.

6.7 Variable speed adjustment knob

Pic. 40

Pic. 41

Pic. 42

Pic. 43

Ensure that the bore of the head stock is clean.

The drive centre has a number 2 Morse Taper

that fits into the head stock. Push the centre

into the head stock bore firmly, and ensure that

it is securely located. To remove the centre,

push the rod into the back of the head stock,

and give it a sharp knock. This will remove the

drive centre.

Note

: Never leave the rod in the

head stock with the machine running.

6.5 Fitting the face plate

Reverse the removal procedure, described

earlier.

6.6 Lathe controls

Emergency stop button

The emergency stop button will lock in the OFF

position when fully depressed. To reset it, twist

clockwise and it will pop out.

Forward / Reverse switch

The forward / reverse switch selects the

direction of the rotation of the spindle. The

forward / reverse switch must only be used

once the spindle has come to a complete stop.

Start / Stop

The start / stop buttons start the motor and the

rotation of the spindle.

Speed display

The speed display shows the RPM of the

spindle.

Variable speed adjustment knob

The Variable speed adjustment knob adjusts

the spindle speed.

Spindle

lock

Face plate

hole

spindle

lock

Drive centre removal shaft

drive centre

Emergency stop button

Start / Stop

Forward / reverse switch

Speed

display

Variable speed adjustment knob

Pic. 44

Pic. 46

Increase speed

Decrease speed

Head stock clamp lever

Summary of Contents for LAGUNA Revo 1836

Page 2: ...2 www igmtools com...

Page 19: ...19 www igm cz...