-12-

www.igmtools.com

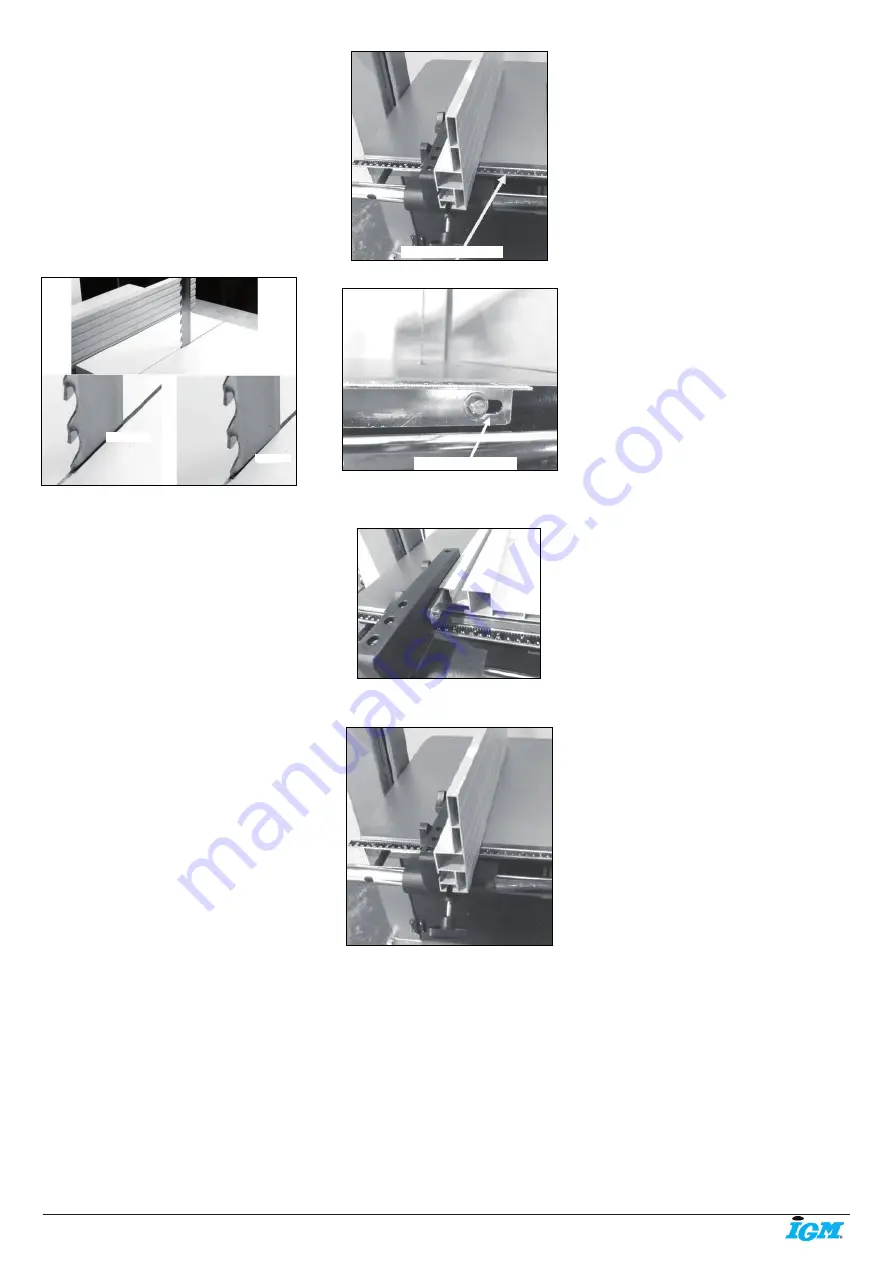

Adjusting the fence for drift

Method 1

1. Make a straight pencil line on the edge of a

board.

2. Feed the wood into the blade cutting next

to the pencil mark. If the blade is drifting, you

will have to compensate by angling the wood

to keep the cut straight.

3. Stop the cut in the middle of the wood and

mark (with pencil) the angle on the table. This

is the angle of drift, and you will have to set the

fence to the pencil line.

4. To adjust the fence, loosen the clamp bolts

that attach it to the cast bracket. Move the

fence so that it lines up with the pencil mark on

the table and retighten the clamp screws.

Pic. 51

Method 2

1. Set the fence parallel with the blade by

loosening the clamp screws that hold it to the

cast bracket. It is not important that it is exact

because you will be readjusting later in the

procedure.

2. Using a piece of scrap wood, make a cut

while holding the wood against the fence. Stop

the cut in the middle of the wood.

3. Look at the position of the back of the blade

within the saw cut. The back of the blade

should be in the center of the slot, but you will

probably find that it is closer to one side.

4. Slightly loosen the clamp screws and adjust

the fence to compensate. Repeat steps 2, 3

and 4 until the blade is centered.

Note

: You may have to do several fine

adjustments, and it is better to do several small

adjustments until you become skilled at the

procedure. Once you have mastered the

process, it should only take a minute to perform

the adjustment.

Note

: Each blade has a slightly different drift,

and each time you change a blade, you must

check and readjust if necessary.

Note

: It is worth taking the time to set the fence

accurately as it will save frustration and

enhance the performance of your machine.

Adjusting the table rule

There is a rule that is fitted to the side of the

table and can be used as a quick guide on the

distance that the fence is from the blade.

Note

. The rule will have to be adjusted each

time the fence is adjusted for drift, as this will

change the distance the fence is from the

blade.

Once the fence has been adjusted for drift:

1. Lock the fence to the rail.

2. Measure the distance from the front of the

blade to the fence.

3. Check the distance indicated on the rule.

4. Loosen the clamp bolts and adjust the rule.

5. Tighten the clamp bolts and recheck.

Pic. 52

Pic. 53

Fence position

Fence in low position

Pic. 54

Fence in high position

Pic. 55

The aluminum fence can be used in two height

positions (high and low). The low position is

handy for cutting thin wood and is used where

the fence in the high position would make it

awkward to complete cuts. The fence in the

high position is used for supporting tall work.

Changing the fence height.

1. Loosen the clamp screws that are located on

the cast bracket.

2. Slide the aluminum fence off the cast iron

bracket.

3. Slide the aluminum fence back onto the

bracket using the second slot and retighten the

clamp screws.

Resawing.

Resawing is the process of cutting a board in

half along its height. The bandsaw is perhaps

the most creative tool in the shop because of

its ability to cut thick or thin, straight or curved.

The ability to cut thick stock such as re-sawing,

making veneers, book matching or cutting

flitches from small logs has great appeal to the

woodworker. These capabilities greatly enhance

he woodworker’s design ability without the

need for additional equipment. When a board

is resawed and the two pieces are lying next

to each other, you will note that they are mirror

images of each other. When these two boards

are glued together, it is called bookmatching.

Note: It is unsafe to cut wood that is

unsupported by the table and should never

be attempted. This is especially important to

note when cutting round logs.

8.2 Selecting the Right Blade

Introduction

The selection and use of blades is a very

extensive subject, and there have been many

books written on it. This section of the manual

is intended as a general guide only.

Selecting a blade

Using the correct blade is important, as it is the

first step in attaining good bandsaw

performance. The most frequently asked

question is „How do I decide on the correct

blade to use?“ The answer is not simple, and

we will explore it in this section of the manual.

Firstly, there is

NO

ideal blade that will do

everything. The blades that you choose will be

determined by the type of work that you are

doing. Large-tooth wide blades are selected

for fast course cuts, and fine, thin blades are

used for intricate scrollwork. You will find that

you will need a large selection of blades if you

do a lot of varied work and fewer blades if you

are concentrating on one section of bandsawing

such as re-sawing. Using the wrong blade is the

best way to abuse it. Using a blade for its

intended purpose allows for maximum efficiency

and is the best way to prolong its life.

Blade terms

The amount that the teeth are wider than the

thickness of the backing material. The larger

the set, the larger the saw cut and the smaller

the radius that can be cut. This can also be

an advantage if you are cutting a job that has

a tendency to nip the blade. The smaller the

set, the smaller the saw cut and the larger the

radius that can be cut; the wood waste is less.

On tipped blades (Resaw King) there is no set,

as the tip is wider than the backing material.

Thickness

The thicker the blade, the stiffer the blade and

the straighter the cut. The thicker the band, the

greater the tendency for the blade to break.

Pitch

The size of the teeth. This is usually quoted in

teeth per inch (TPI). The larger the tooth, the

faster the cut because the tooth has a large

gullet and has a greater capacity to transport

large amounts of sawdust through the job. The

larger the tooth, the coarser the cut and the

poorer the surface finish of the cut. The smaller

the tooth, the slower the cut as the tooth has

a small gullet and cannot transport large

amounts of sawdust through the job. The

smaller the tooth, the finer the cut and the

better the surface finish of the cut

Table rule

Adjustment slot

Correct

Adjust