-

15

-

www.igmtools.com

Step 4

Pic. 64

Done

Pic. 65

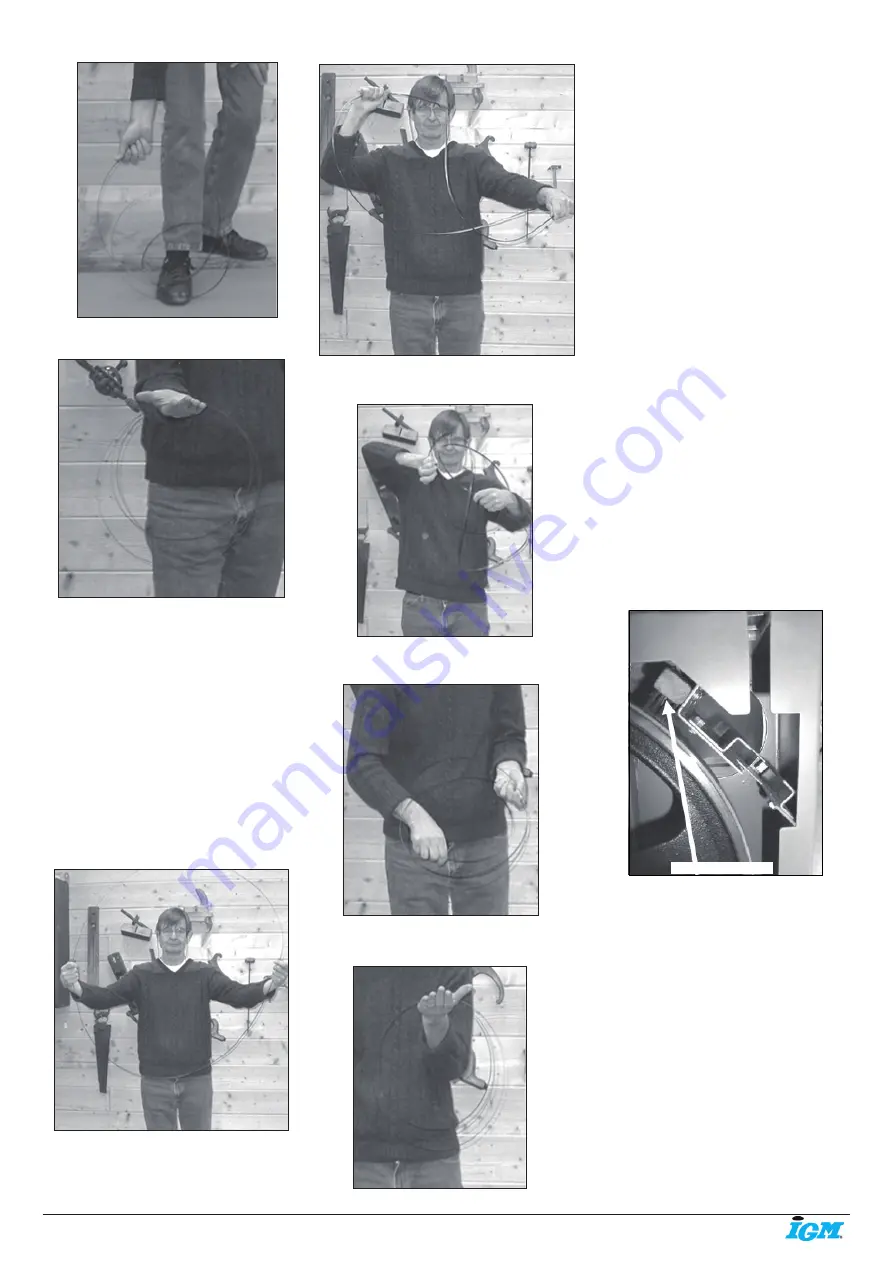

Method 3

The steering wheel method. Start with the blade

in front of you, as if you‘re holding a

steering wheel with your hands at the 9 o‘clock

and 3 o‘clock positions. Simultaneously

twist your left hand up and your right hand

down. As the blade starts to fold, move your

hands closer together while tilting your left hand

to the right and your right hand to the left.

The blade will fall into three coils. A variation of

this method is to hold the blade as above,

but twist both hands inward, so you‘re looking

at your knuckles and the blade will again fall

into three coils.

Step 1

Pic. 66

Step 2

Pic. 67

Step 3

Pic. 68

Step 4

Pic. 69

Done

Pic. 70

9

. Maintenance

All tools and machines require regular

maintenance, and the bandsaw is no exception.

This section details the general maintenance

and care of your bandsaw. In general, we

recommend that you only use a Teflon-based

lubricant on the bandsaw. While regular oil

attracts dust and dirt, Teflon tends to dry and

has fewer tendencies to accumulate dirt and

sawdust on your machine.

Cleanliness and tire maintenance.

One of the major concerns in regards to the

maintenance of the bandsaw is how clean the

tires are. As the saw cuts, some sawdust lands

on the tire of the lower wheel. As the wheel

rotates, the sawdust becomes compressed on

the tire. This is especially true for woods such

as pine. The compressed sawdust could have

a negative effect, such as vibration, short blade

life and drifting of the blade. A brush contacts

the lower wheel and helps to prevent buildup.

You should inspect the tires regularly to check

that buildup is not happening, especially the

lower wheel. The tires are made of rubber

and wear just like car tires. They wear in the

middle, which causes a concavity in the tire.

The deformation makes it hard to track the

blades, and for this reason it is important to

maintain the original shape of the tire. The best

way to clean the tire surface and maintain the

original shape is to sand it with sandpaper.

The old tire surface often hardens and glazes

over and should be redressed occasionally.

This can be done by sanding the wheel with

100-grit sandpaper. This will take off a little of

the rubber and expose new rubber, which is

desirable. Rotate the wheels by hand with the

blade removed.

Pic. 71

Guides

The ceramic side and back guides should be

inspected regularly for cracks and chips. If they

are damaged, they should be replaced as they

could damage your blades and bad guides

will detract from the performance of the

bandsaw. The guides should be cleaned

regularly and any wood gum or dirt removed.

Any commercially available solvent can be

used, and after cleaning they should be

lubricated with Teflon-based lubricant.

Drive Belt

The drive belt should last for many years

(depending on the usage) but needs to be

inspected regularly for cracks, cuts and general

wear. If damage is found, replace the belt.

Tire brush