2

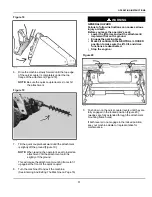

REMOVING AND INSTALLING STANDARD / HEAVY DUTY AUGER TEETH

..................................................... 32

REMOVING AND INSTALLING HYDRAULIC MOTOR AND GEAR BOX

............................................................ 33

ASSEMBLING AND DISASSEMBLING CHAIN REDUCTION DRIVES

............................................................... 34

ATTACHMENT STORAGE AND RETURN TO SERVICE

................................................................................... 37

Auger Dimensions........................................................................................................................................ 38

Performance Specifications............................................................................................................................ 39

Attachment Capacities .................................................................................................................................. 39

TORQUE SPECIFICATION FOR BOLTS

HYDRAULIC CONNECTION SPECIFICATIONS

............................................................................................... 42

O-ring Face Seal Connection.......................................................................................................................... 42

Straight Thread O-ring Fitting.......................................................................................................................... 42

Tubelines And Hoses .................................................................................................................................... 42

Tightening The Flare Fitting............................................................................................................................ 42

O-ring Flare Fitting ....................................................................................................................................... 43

Port Seal Fitting ........................................................................................................................................... 45

Push To Connect Fittings ............................................................................................................................... 45

ATTACHMENT / IMPLEMENT WARRANTY

TABLE OF CONTENTS

Summary of Contents for Auger 75 DDH

Page 2: ......

Page 12: ...10 Figure 4 C221899a SAFETY AND TRAINING RESOURCES ...

Page 29: ......

Page 52: ...50 troubleshooting 29 W warranty 48 welding safety 7 ALPHABETICAL INDEX ...

Page 53: ......