15

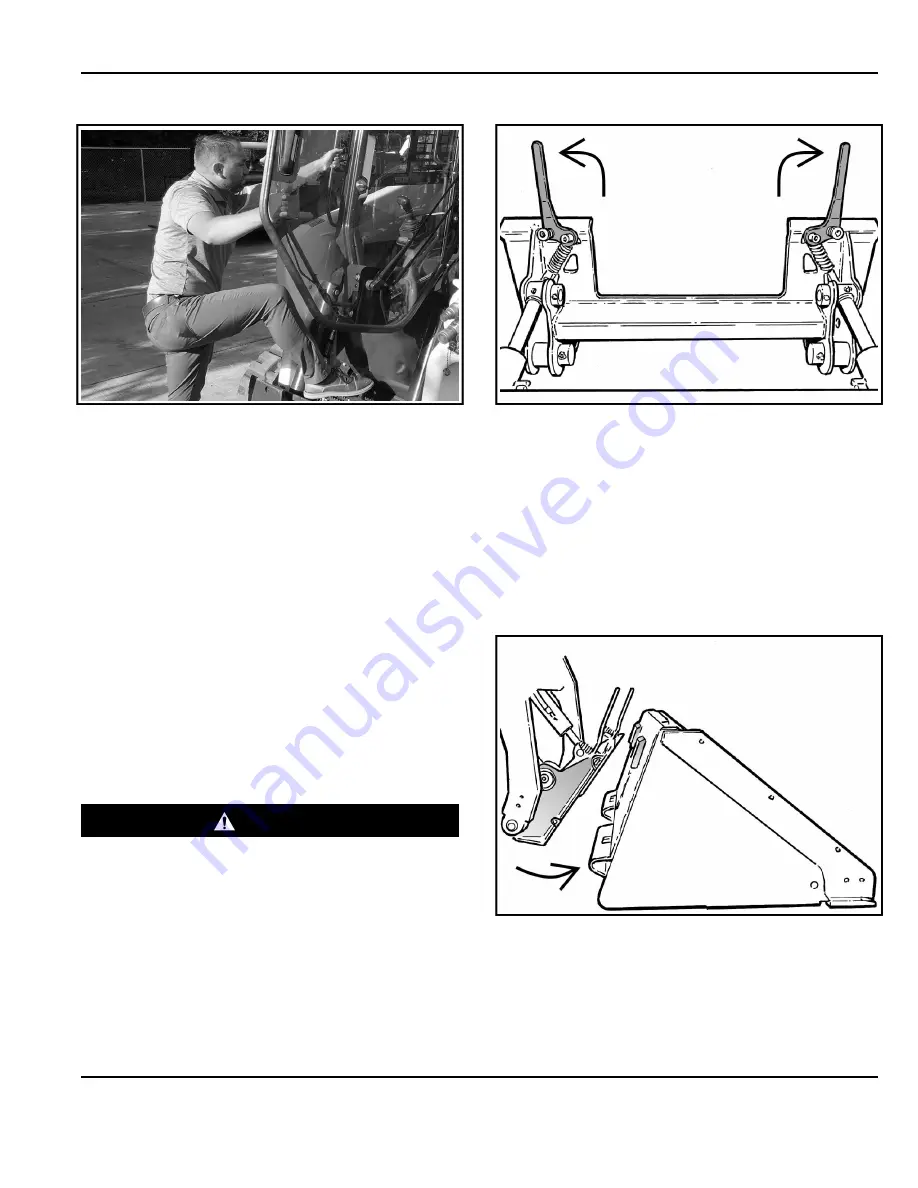

Figure 16

C216077a

•

Use the attachment / implement steps (if equipped),

grab handles, and safety treads (on the machine and

frame) to get in and out of the machine, maintaining

a three-point contact at all times [Figure 16]. Do not

jump.

•

See the machine’s Operation & Maintenance Manual

for detailed instructions on entering and exiting the

machine.

Installing The Attachment

Installing With Non-powered Machine Quick Coupler

The illustrations and instructions provided explain how to

install a bucket attachment onto a machine. Follow these

same instructions if you are installing different

attachments such as a grapple, snow pusher, sweeper,

etc.

The attachment mounting frame for the attachment has a

top flange that is designed to receive the top edge of the

machine quick coupler and the lower part of the frame is

designed to receive the quick coupler wedges.

WARNING

GENERAL HAZARD

Failure to obey warnings can cause serious injury or

death.

Obey all warnings on the machine and in the

manuals.

◂

W-2744

Always inspect the machine’s quick coupler and the

attachment mounting frame before installation. (See the

machine’s Operation & Maintenance Manual.)

(See Daily Inspection on Page 11)

Figure 17

NA3445A

1.

Pull the quick coupler levers up until they are fully

raised (wedges fully raised) [Figure 17].

2.

Enter the machine.

3.

Turn the machine on.

4.

Release the parking brake.

5.

Lower the lift arms and tilt the machine quick coupler

forward.

Figure 18

NA3446a

6.

Drive the machine slowly forward until the top edge

of the quick coupler is completely under the top

flange of the attachment [Figure 18].

NOTE:

Be sure the quick coupler levers do not hit

the attachment.