18

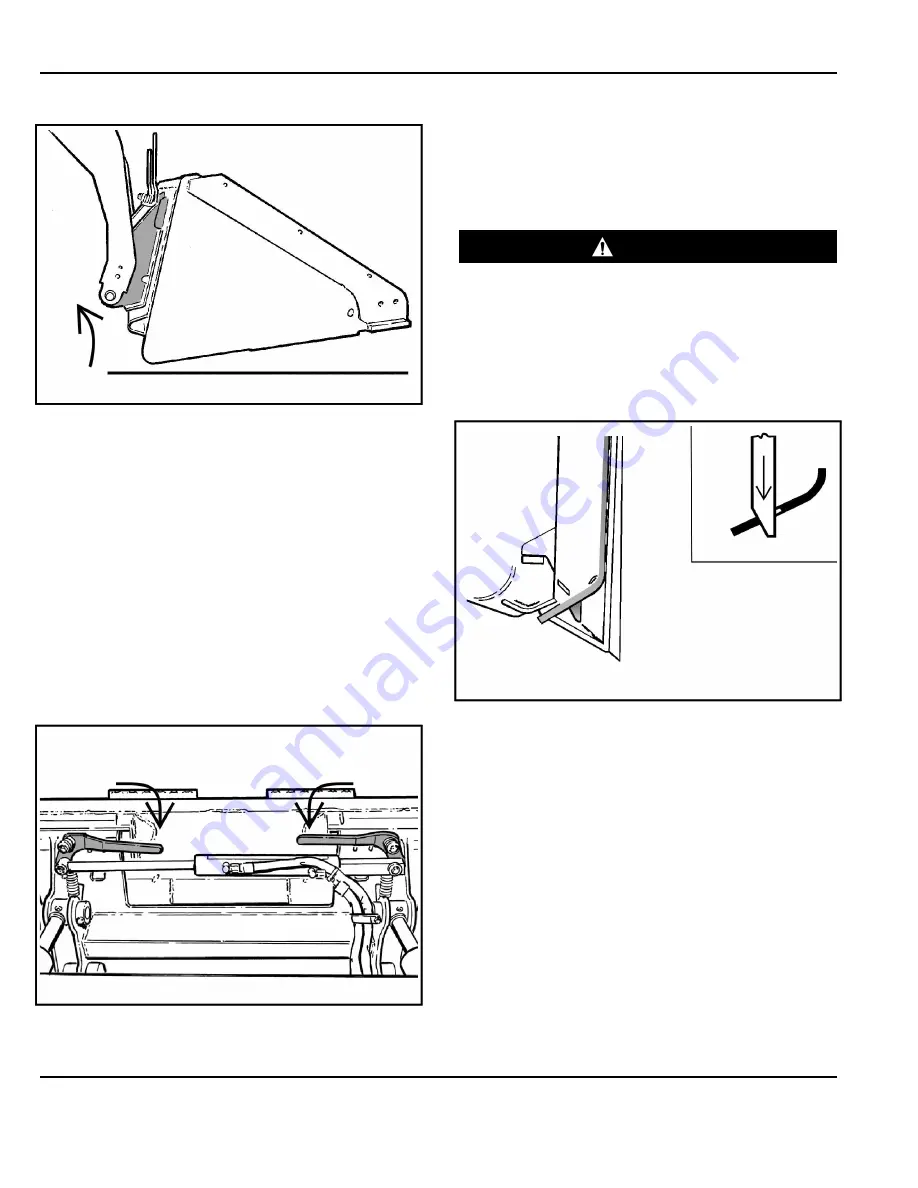

Figure 24

NA3447a

7.

Tilt the quick coupler backward until the attachment

is slightly off the ground [Figure 24].

This will cause the attachment mounting frame to fit

up against the front of the quick coupler.

Some powered quick coupler system have

continuous pressurized hydraulic oil to keep the

wedges in the engaged position and prevent

attachment disengagement. Because the wedges

can slowly lower, the operator may need to

reactivate the powered quick coupler to be sure both

wedges are fully raised before installing the

attachment.

8.

Operate the powered quick coupler until the levers

are fully raised (wedges fully raised).

Figure 25

NA3454A

9.

Operate the powered quick coupler until the levers

are fully engaged in the locked position [Figure 25]

(wedges fully extended through the attachment

mounting frame holes).

If both levers do not engage in the locked position,

see your machine dealer or representative for

maintenance.

WARNING

CRUSHING HAZARD

Failure to secure attachment coupler wedges can

allow attachment to come off and cause serious

injury or death.

Both wedges must extend through the holes in the

attachment mounting frame. Levers must be fully

down and locked.

◂

W-2715-EF

Figure 26

NA3450A

10. The wedges must extend through the holes

[Figure 26] in the attachment mounting frame,

securely fastening the attachment to the quick

coupler.

11. Lower the lift arms and put the attachment flat on the

ground.

12. Turn the machine off and exit the machine.