OPERATION

IC120 ENG

3-7

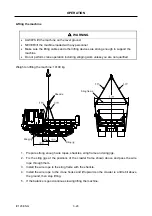

TRAVELING THE MACHINE

Start-travel-stop

WARNING

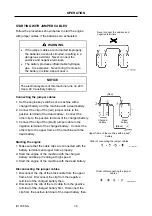

When traveling, lower the body completely.

Lock the rear gate and side gates firmly.

Make sure that no persons are around the

machine. Sound the horn before starting.

1. Adjust the traveling speed properly with the travel

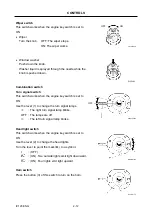

speed select switch (1).

2. Turn the engine throttle dial (2) to increase the engine

speed to the necessary speed.

3. Push down on the no-mark position of the parking

switch (3) to deactivate the brake.

Make sure that the mark lamp is off.

4. Use the travel lever as shown below.

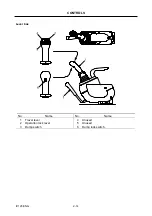

Forward: Push the travel lever forward.

Stop:

Set the travel lever to the neutral position.

Backward: Pull the travel lever backward.

Increase the travel lever stroke to raise the speed.

Decrease the stroke to reduce the speed.