MAINTENANCE

IC120 ENG

4-1

4

PRECAUTION ON MAINTENANCE

Maintenance intervals

Determine the maintenance intervals in accordance with the time of the hour meter and certain

period of time.

This section shows the maintenance intervals on the assumption that the machine is used in

normal running conditions. Carry out maintenance earlier if the work environments are bad or

severe.

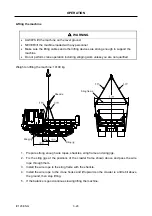

Preparation for maintenance

Place the machine in a flat and rigid ground.

For normal maintenance, lower the body completely.

To carry out maintenance with the body raised, raise the body fully and apply the safety lever.

Set the parking switch to the brake ON position and the operation lock lever to the locked

positions. Stop the engine and pull out the key from the engine key switch.

Put a tag, which indicates that maintenance is being carried out, on the engine key switch or

control lever at an easy-to-see position.

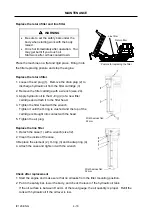

Cautions for repair works requiring welding

Turn off power. (Disconnect the cable from the negative terminal of the battery.)

Do not put any seals, bearings or the like between the weld zone and GND.

Do not connect the GND wire to the pin of the body or hydraulic cylinder. It is the best way to

connect the GND wire at or near the object to be welded.

Use genuine parts.

Be sure to use the genuine parts.

Use oil and grease of viscosity appropriate to the temperature.

Ask IHI’s sales service dealer for important maintenance.

Ask IHI’s sales service dealer for important maintenance works such as replacement of electronic

parts, adjustment of the hydraulic pressure and so forth that require professional knowledge and

technique.