Astria.us.com

126753-01M

11

INSTALLATION

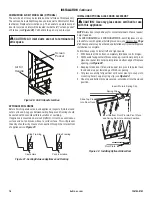

Figure 13 - Removing Front Refractory Access Panel

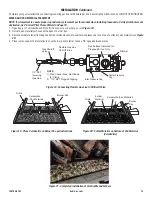

INSTALLING WIRELESS HAND-HELD REMOTE CONTROL MRC SERIES

NOTE:

If using optional wireless hand-held remote control, the wall switch is no longer operational.

Installing Receiver

1. Remove front refractory access panel by lifting up and angling out of firebox opening

(see

Figure 13

)

to expose controls.

2. Locate brown "wall switch wire" that is connected to the valve. Strip the ends of the brown wire to expose one red and one white wire. These

wires shall be connected the remote receive box or wall switch (figures 14 & 14A). The remote receiver can be placed either in the bottom

of the firebox (figure 14B) or mounted in a convenient location on the wall.

3. See remote instructions for further information.

Conduit Sleeve

Route Millivolt

Through Gas Line

To Thermopile

and Switches

Wires (Supplied)

Wall Switch

(Not Supplied)

(Back View)

IN

TH

TP

THTP

IN

OUT

O

F F

PI

LO

T

ON

NOTE:

If any of the original wire as

supplied must be replaced, use 18 AWG

TYPE CL2 (UL) 105 C (25 ft. length

MAXIMUM) or equivalent.

Wall Switch or Remote

Control (Not Supplied)

Figure 14 - Wall Switch Wiring Diagram

Figure 14A - Remote Receiver

Figure 14B - Remote Receiver on Firebox Bottom

WARNING: Do not wire remote wall switch to main

power supply (Standard 120v household current).

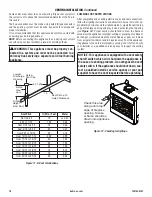

WALL SWITCH INSTALLATION

The installation of a wall switch allows you to activate the gas control

valve without normal household electricity since valve operates on

millivolt current supplied by heat generated by the thermopile. To

install wall switch:

1. Remove front refractory access panel by lifting up and angling

out of firebox opening

(see

Figure 13

).

2. Use wire and connectors provided. Attach red wire to terminal

marked TH/TP on control valve. Attach white wire to blade con-

nector on open end of safety circuit wiring

(see Wiring Diagram,

Page 20

).

NOTE:

If any of the original wire from unit control must be replaced,

use the same type or a higher rated wire (25 ft. maximum length).

3. Locate wall switch in a convenient location.

4. After wire connections are complete, replace refractory access

panel.